1-10kg Powder Filling Machine

| Packaging range | 1-10kg |

| Packing speed | 500-1500bags/h (according to the packaging size and products) |

| Packaging accuracy | ±1% |

| Dimension | 1000*850*1850mm |

| Weight | 280kg |

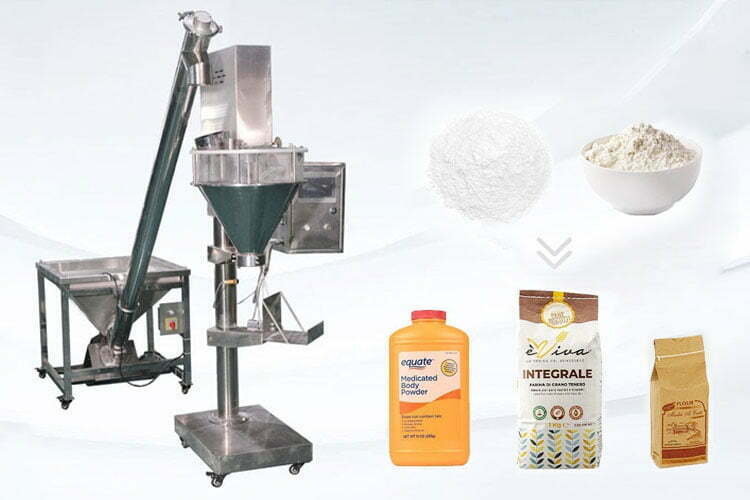

Powder filling machine here is a tool to fill powder within 1-10kg efficiently and reliably. The same as other powder packing machines, it’s equipped with an auger that measures the volume of filling material. The equipment is suitable for various kinds of powders, such as milk powder, flour, starch, condiment, chili powder, detergent powder, chemical powder, farm, and sideline products, additive powder, dyes powder, fodder powder, etc.

In order to pack more efficiently, you can use it by matching it with some devices. For instance, it’s better to buy a bag sealing machine together if you also want to seal the bag. While if you use bottles for packaging, you can purchase a conveyor belt to save labor. Furthermore, OEM service is available according to your needs.

Features & benefits of dry powder weighing and filling machine

- Reasonable design, simple structure, easy to install, operate and maintain

- Automatic quantitative weighing, filling, and adjusting metering error

- Keys and PLC touch screen are optional based on your needs

- Add a big clamp on the discharge port to fix the packaging bag for filling a big volume

- Changing different sizes of auger can control to package different volume of material

- Adopt quantitative weighing system, accurately, efficiently, and conveniently

- Use stepper motor and electronic weighing technology, high precision

- Suitable for filling packaging bag, bottle, and cans

- Customization service available

Semi-automatic powder filling machine parameters

| Power | AC380V 900W |

| Packaging specifications | 1-10kg |

| Packaging accuracy | ±1% |

| Packing speed | 500-1500bags/h (according to the packaging size and products) |

| Dimension | 1000*850*1850mm |

| Weight | 280kg |

1-10kg powder auger filler machine structure

The auger filler consists of a material hopper, the discharge outlet, electronic control panel, tray, screw conveyor with a hopper, and a motor. The material hopper is used for storing powder for filling. A discharge outlet with an auger is to control filling volume. For large bag filling, it will be equipped with a clamp device to fasten the bag. The tray has a supporting function for bags, bottles, or cans. There are two kinds of control panels optional, keys and a PLC touch screen. Screw conveyor transports material into filling machine’s hopper by the power of its own motor.

In addition, we support customized machines according to your needs. You can get in touch with us to get more details by filling out the form at the bottom of this article.

Screw conveyor parameters

| Power | AC380V 1100W |

| Elevating capacity | 1000-3000kg/h |

| Capacity of hopper | 100-300kg |

| Height of filling device | 2000mm( support custom service) |

| The material of the equipment | Stainless steel |

| Weight | 150kg |

Wide applications in food & non-food, bags, bottles, or cans

The powder filling machine for 1-10kg is suitable for a variety of powder, such as milk powder, coffee powder, flour, cornflour, rice flour, milk-tea powder, albumen powder, starch, spices, matcha powder, cocoa powder, pepper, chilli powder, black pepper, cumin, curry, masala, dyes powder, pesticide powder, additive, fodder powder, etc. And the filling equipment applies to bags, bottles, and cans.

Related machines from Henan Top Packing Machinery

If you want a production line with the 1-10kg powder filling machine, there are many machines optional in Henan Top Packing Machinery, such as conveyor belts for bottles or cans, continuous bag sealing machine, capping machines, vacuum sealing machine, date printer, carton sealing machine, and so on. Besides, we also provide powder packing machines for 0-80g/bag, 20-200g/bag, 500-1000g/bag, 1000-3000g/bag, 5-50kg/bag, etc. Furthermore, we support customization services. Contact us for more information and the best price.

Conclusion

Powder filling machines are an essential tool in various industries such as pharmaceuticals, food and beverage, chemicals, and agriculture. These machines are used to fill powders into containers with a high level of accuracy and consistency. They are available in different types, including auger filler, volumetric filler, and gravimetric filler, each with its own unique features and uses. Key features of powder filling machines include speed and accuracy, precision and consistency, ease of use and maintenance, and safety features. With the continued growth and advancement of technology, powder filling machines will continue to play a vital role in ensuring efficient and effective production in a variety of industries.