Food packaging machine

| Brand | Shuliy |

| Packing speed | 30-180bags/min |

| Bag forms and shapes | Back seal, three-side seal, four-side seal, gusseted bag, punched bag, zipper bag |

| Applications | Grains, nuts, snacks, fruits, vegetables, popcorn, potato chips, corns, etc. |

| Advantages | High efficiency, various machines for choice, customization |

| Service | Professional product consultation and after-sales service, warranty |

Shuliy food packaging machine is used for measuring, filling, sealing, and packaging of various food of powder, granules, liquid, paste, pieces, etc. into pouches with a packing speed of 30-180 bags per minute. Its packaging styles have a back seal, 3-side seal, and 4-side seal.

There are optional devices that can match food packing machines for more functions, such as loading conveyors, output conveyors, date printers, nitrogen filling devices, the mold of sealing and cutting devices with a puncher, etc. You can choose based on your needs.

Different types of food need different packaging machines, such as granule packaging machine for granular food and powder packaging machine for powder. Thus, it’s widely used in casual food, spices, frozen food, baked food, nuts and fried food, candy, grain and oil and other industries. If interested, get in touch with us and continue to read for more details!

Types of food packaging machines for sale

The food packing machines for sale in Shuliy mainly include:

- Powder packing machine

- Granule packing machine

- Liquid/paste packing machine

- Pillow packing machine

- Vacuum packing machine

- Shrink wrapping machine

The above are commonly packing machines for food products. Then, we will introduce some of them for your reference. If want more details, you can directly contact us at any time!

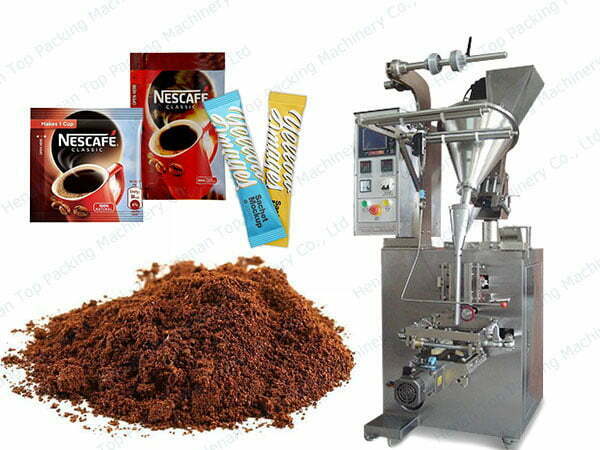

Food powder packaging machine

This machine is used for powdery food package into small sachets pouches. Its weight is 0-200g, 0-1kg, 1-3kg, 1-10kg, or 10-50kg per bag. It’s suitable food powders include seasoning powder, soy milk powder, coffee powder, flour, black sesame powder, sweet potato powder, etc. According to different packaging needs, we will recommend different packaging machines for food for you.

The following are two hot-selling food powder packing machine models and parameters for your reference. If you’re interested, contact us immediately!

0-200g powder pouch packing machine parameters

- Packing style(bag style): 3-side seal/back seal/4-side seal

- Packing speed: 20-80bags/min

- Power consumption: 1.8kw

- Weight: 250kg

- Dimensions: 650*1050*1950mm

- Packing weight: 0-200g

- Bag width: 20-150mm(replace the bag former)

- Bag length: 30-180mm(adjustable)

1-3kg powder packaging machine parameters

- Bag length: 80-400mm(L)

- Bag width: 80-250mm(W)

- Max width of roll film: 520mm

- Packing speed:5-50bags/min

- Measuring range: 3000ml(Max)

- Air consumption:0.65Mpa

- Gas consumption:0.4m³/min

- Power voltage: AC220V/50HZ

- Dimension: (L)1150×(W)1795×(H)11650mm

- Deadweight of machine: 600kg

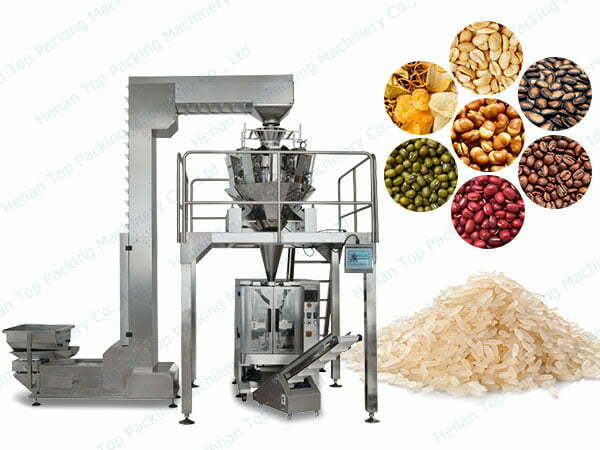

Food particle counting packing machine

It’s a granule packing machine suitable for granular food, with filling weights of 0-200g, 0-600g, 100-1000g, and 150-6000g. This food packaging machine can pack chips, melon seeds, candy, peanuts, cashew nuts, etc., into pouches. We can offer the best solution to fit your food packaging demands. Here are the parameters of the food pouch packing machine for your reference.

If want more details, please refer to: granule packing machine.

SL-520 multi-head weigher packing machine parameters

- Film width: Max.520mm

- Bag length: 80-350mm

- Bag width: 100-250mm

- Film diameter: Max.320mm

- Packing speed: 5-60bags/min

- Measuring range: 2000mm

- Voltage & power: 220v 50/60HZ 3KW

- Dimension: 1488*1080*1490mm

Horizontal packing machine for food

This industrial food packaging machine is commonly used for strip items, such as vegetables, bread, biscuits and others. Similar food can be packed by this flow wrap machine. It has 4 popular models: SL-250, SL-350, SL-450, and SL-600. Below are the SL-450 food bar packaging machine specifications. If want more details about this kind of packaging machine, welcome to contact us at any time!

SL-450 pillow packing equipment parameters

- Film width: Max 450mm

- Bag length: 130-450mm

- Bag width: 50-80mm

- Product height: Max.70mm

- Packing speed: 30-180bags/min

- Power: 220V,50/60HZ, 2.6KVA

- Weight: 900kg

- Dimension: 4020*745*1450mm

Vacuum packaging machine for food

This food vacuum pack machine is used to keep food fresh and prolong the shelf life. It’s usually for meat, vegetables, grains, etc., in a vacuum pack. This kind of food packaging machine includes single-room vacuum sealer, double-room vacuum sealer, table vacuum sealer and stretch film vacuum sealer. The following are the parameters of the double chamber vacuum packaging machine.

Want more details? Please read vacuum packaging machine.

Double chamber vacuum sealer parameters

- Voltage: 380V/50HZ

- Vacuum pump power: 1.5KW

- Sealing power: 1.17KW

- Absolute pressure: 0.1pa

- Number of sealing strips: 2

- Sealing strips size: 500mm*10mm*2

- Chamber material: 304 stainless steel

- Cover material: organic glass

- Chamber size: 560*525*160mm

- Machine size: 1260*605*960mm

- Machine weight: 150kg

Wide application of industrial food packaging machine

Our commercial food packaging machine has a wide application of powder, granules, liquid/paste, etc. Please see the followings in detail.

Applicable powder includes:

- Seasoning powder

- Chili powder, pepper powder, curry powder, garlic powder, ginger powder, onion powder, salt (refined salt, seasoned salt), five-spice powder, chicken powder, shiitake mushroom powder, seaweed powder, sesame powder, etc.

- Beverage/brewing powders

- Milk tea powder, coffee powder, soy milk powder, cocoa powder, cereal powder, solid beverage powder(lemon powder, fruit juice powder), protein powder, etc.

- Bakery powders

- Flour, glutinous rice flour, corn starch, baking powder, milk powder, etc.

- Nutritional/health powders

- Meal replacement powder, spirulina powder, black sesame powder, soybean powder, oat powder, barley powder, eggshell calcium powder, barley wakame powder, etc.

- Agricultural product powders

- Sweet potato flour, potato flour, kudzu flour, cassava flour, pumpkin flour, jujube flour, etc.

- Granules: coffee beans, tea, broad beans, melon seeds, snacks, sugar, peanuts, cashew, seeds, rice, biscuits, nuts, and so on.

- Liquid/paste: water, milk, juice, soy milk, yogurt, soda water, wine, beer, tomato sauce, peanut butter, etc.

- Vacuum seal: sausage, bacon, dried tofu, beef, pork, chicken, vegetable, fruit, rice, tea, peanut, nuts, dried fruit, biscuit, corn, flour, grain, etc.

- Pillow pouch pack: bread, candy, moon cake, sandwich, biscuit, vegetable, fruit, and so on.

Benefits of automatic food packaging machine

- It can complete 3-180 bags per minute, significantly improving the efficiency of the production line and reducing the time and cost of manual operation.

- Our machine can ensure the consistent packaging quality of each bag of food, avoiding the errors and irregularities brought by manual operation.

- The automatic packing machine can make food packaging more beautiful and improve the market competitiveness of products through precise packaging forms and equipment configuration.

- The equipment is made of food-grade materials, which are healthy, environmentally friendly and easy to clean.

- Shuliy has many kinds of packing machines for food, like granule packing machine, powder packing machine, pillow packing machine, etc.

- We can customize the screw feeding, multi-head weigher, liquid pump and other metering systems according to customer product characteristics

Do you know the food packaging machine price?

The price of the commercial food packing machine varies according to the type of equipment, functional configuration, production capacity, degree of automation and other factors. Generally speaking, the following aspects will affect the price:

- Packaging method and bag type

- Machine capacity

- Customized requirements

- Degree of automation

- Brand and quality

If you want to know more information about our products, contact us today to get a free quotation.

Tips about choosing a suitable food packaging machine

Choosing the right food pouch packing machine is not only about efficiency and production capacity, but also about long-term use results and cost recovery. Here are some selection tips:

- Define the packaging needs

- Consider the production capacity

- Degree of automation

- Equipment maintenance and service

- Comprehensive cost assessment

If you are ready to invest in a food packaging machine to start your business, contact us soon and we will do our best to provide good service for you.

Contact us for the best price!

f you are looking for an excellent food packing machine, it is a good idea for you to contact us for more product profiles or the best price!

We promise to provide each customer with:

- Professional product consultation

- Transparent price system

- Customized service

- Fast delivery cycle

Welcome to contact us for more details and quotes to help your food packing business run more efficiently!