Popcorn packing machine

| Machine name | Popcorn pouch packaging machine |

| Packing range | 0-6000ml |

| Packing speed | 5-100bags/min |

| Optional packing machine for popcorn | Granule packing machine and multi-head weigher and packer |

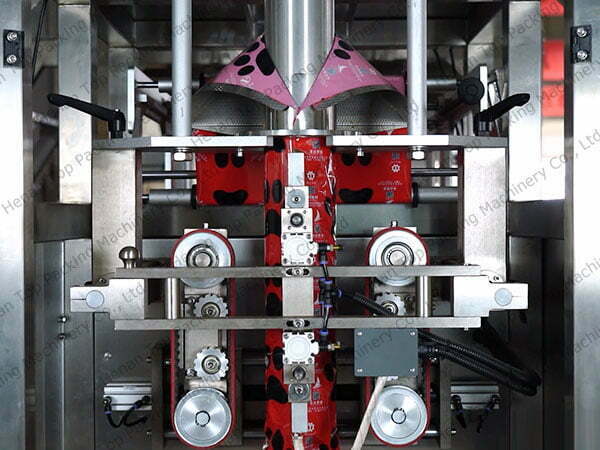

| Packaging style | Back seal, 3-side seal and 4-side seal |

| Customization | Bag length, bag width, machine power & voltage, etc. |

Shulit popcorn packing machine is used for popcorn and other puffed food packaging into pouches, which can efficiently complete measuring, filling, and sealing operations. It’s suitable for a packaging specification of 0-6000ml and a packing speed of 5-100 bags per minute.

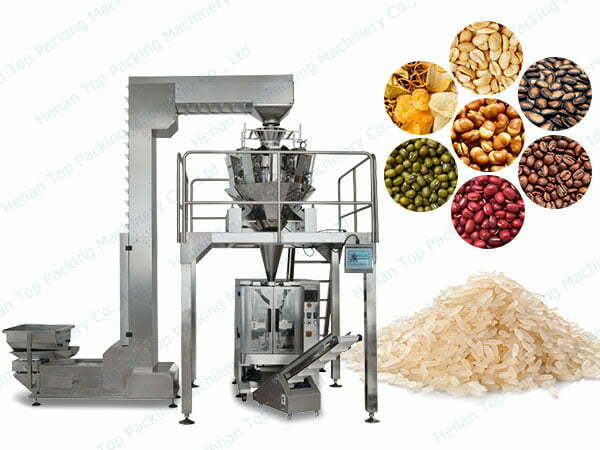

As a professional packing machine solution provider, we have 2 types of granules packaging machines for popcorn: VFFS granular packing machine(SL-320 & SL-450) and multi-head lapel packaging machine(SL-420, SL-520 & SL-720). The following is a detailed description of these two types of equipment for your reference when choosing popcorn pouch packaging.

Type 1: Small vertical popcorn pouch packaging machine for sale

This kind of popcorn packing machine is a small vertical packaging machine, having a compact design, suitable for limited space. It has high-precision measuring cups to ensure consistent weight of each bag of popcorn with minimal error.

The popcorn packaging equipment has a packing range of 0-600g per bag and a packing speed of 20-100 bags per minute. If want more details, welcome to contact us at any time!

Small vertical type popcorn filling sealing machine parameters

| Model | SL-320 | SL-450 |

| Bag style | Back seal/3-side seal/4-side seal | Back seal/3-side seal /4-side seal |

| Packing speed | 32-72bags/min or 50-100bags/min | 20-80bags/min |

| Bag length | 30-180mm | 30-180mm |

| Bag width | 20-145mm(need to replace the former) | 20-200mm |

| Power consumption | 1.8kw | 1.8kw |

| Weight | 250kg | 420kg |

| Dimensions | 650*1050*1950mm | 750*750*2100mm |

The model is named by the maximum width of roll film. Its actual packaging weight suitable depends on the width and length of the bags. A nitrogen filling device is available to match for keeping popcorn’s taste.

Type 2: Multi-head combination weigher popcorn packing machine

The multi-head weighing packaging machine works with multiple weighing heads at the same time, greatly improving the metering speed and packaging speed. It can complete 5-50 bags per minute and the weight per bag is 150-6000ml, suitable for large-scale production needs.

Its high-precision weighing system ensures that each bag of popcorn weighs the same with minimal error, while adapting to different sizes and shapes of popcorn. Are you interested? If yes, get in touch with us for more!

Muli-head combination scale packing machine technical data

| Type | SL-420 | SL-520 | SL-720 |

| Bag length | 80-300mm(L) | 80-400mm(L) | 100-400mm(L) |

| Bag width | 50-200mm(W) | 80-250mm(W) | 180-350mm(W) |

| Max width of roll film | 420mm | 520mm | 720mm |

| Packing speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Air sonsumption | 0.65Mpa | 0.65Mpa | 0.65Mpa |

| Gas consumption | 0.3m3/min | 0.4m3/min | 0.4m3/min |

| Power voltage | 220VAC/50HZ | 220VAC/50HZ | 220VAC/50HZ |

| Dimension | 1150*1795*11650mm | 1150*1795*11650mm | 1780*1350*1950mm |

| Deadwight of machine | 540kg | 600kg | / |

The numbers 420, 520, and 720 of models are the maximum width of roll film. This multi-head weigher not only can match the lapel packing machine but also can combine a pre-made packaging machine. The final packaging volume is determined by the size of the pouches. It can add a nitrogen-filling device to the sealing part.

Advantages of popcorn packing machine

- It can complete the packaging of 5-100 bags per minute, which greatly improves the production efficiency.

- This popcorn bagger adopts an advanced weighing system with small errors to ensure accurate portioning of each bag of popcorn.

- The popcorn packaging equipment has a humanized design and friendly operation interface, supporting quick adjustment of parameters.

- It can handle different shapes and sizes of popcorn and adapt to a variety of packaging materials (e.g. plastic bags, aluminum foil bags).

- The machine is made of food-grade materials, conforming to food safety standards, ensuring a clean and hygienic packaging process.

- We can customize the bag length, bag width, machine power and voltage, bag style, etc.

Applications of automatic popcorn packing machine

Our packing machine for popcorn is not only suitable for popcorn, but also can be used to package other kinds of food, such as:

Fava beans, sugar, seeds, dates, potato chips, banana chips, nuts, salt, candy, coffee beans, and so on.

The following industry always uses the popcorn pouch packaging machine to benefit their business:

- Food processing industry: for packaging of puffed food such as popcorn, potato chips, nuts and so on.

- Retail and wholesale market: for small bag retail packaging or big bag wholesale packaging.

- Movie theaters and entertainment venues: provide efficient packaging solutions for popcorn retailing.

- E-commerce and logistics industry: to meet the transportation and sales needs of pre-packaged popcorn.

What’s the popcorn packing machine price?

The popcorn packaging machine price is concerned with different components of the equipment, technologies, and quality.

One of the most important machine materials is stainless steel, which is strong, durable, and easy to clean. The stainless steel price in the market influences the machine price in a way. Besides, usually, the more advanced technologies are used, the price is higher. Our popcorn packaging machine for sale with advanced technologies is more intelligent in operation.

Meanwhile, the quality also affects the price of popcorn baggers. Quality refers to the life of machines. It’s not only the quality of the machine itself but the package system for it before shipment. Besides, the machine freight is different for different countries.

If you want the specific machine price, contact us now and we’ll provide the detailed quotation according to your needs for your reference.

Why choose us as popcorn packing machine supplier?

We have had quite professional technical staff in the packing machine industry for nearly 30 years. Our popcorn filling machine has advanced microcomputer chip control that runs stably, with low noise, long life, and high efficiency. Besides, the microwave popcorn packaging machines sold by us are strictly inspected time after time before shipment, taking photos and videos for you.

If you have any questions about the machine, we will get back to you, and solve them as soon as possible. And we provide a 24-hour online service to guide you on how to install and replace parts. In addition, we also have lifetime maintenance, an English manual, and video teaching. We will do our best to satisfy every client.

Contact us to get the best quote!

If you are interested in our popcorn pouch packing machine, contact us today for a more useful product profile. We customize the machine to meet your popcorn packaging demands. All in all, we will try our best to help your business.