Granule packing machine

| Hot-selling model | SL-320 and SL-450 |

| Applications | Rice, sugar, cookies, nuts, seed, grains, popcorn, candy, potato chips, etc. |

| Warranty | 12 months |

| Note | Custom service available |

Shuliy granule packing machine is automatically weighing, bag forming, filling, sealing and cutting for granular products with good fluidity. It can pack rice, sugar, peanuts, cashew nuts, seeds, popcorn, tea, potato chips, snacks, pills, candy, coffee, cereal mix, etc.

This granule pouch packing machine can pack items into sticks or sachets with different weights, such as 200g, 600g, 1000g, etc. It can pack granules into back seal, 3-seal and 4-seal styles.

We have different types of granules packaging machines for sale, like small granule packing machine(SL-320 & SL-450), chain bucket packing machine(SL-420) and multi-head weigher and packer.

Besides, we support OME service to fit your packing requirements. Welcome to contact us for more details!

3 types of automatic granule pouch packing machines for sale

Type 1: small vertical granule packing machine

This type of automatic granule filling packing machine is the most popular granuler package. There are 2 types available: SL-320 and SL-450. Read on for more details.

SL-320 small granule granular filling packing machine

This machine can pack granular in pouches with a weight of ≤200g. It can pack 20-80 bags per minute. The bag style can be back seal and 3-side seal. The 4-side seal also can be customized.

It’s made of stainless steel, and the max. film width is ≤30cm.

SL-450 granules packing machine

This type of granular packaging machine has a packing weight of ≤600g. It can pack 20-80 bags per minute also. Its packing style is back seal and 3-side seal. According to your requirements, we can also customize the 4-side seal.

The machine material is stainless steel and the mx. film width is ≤43cm.

The bag width is 20-200mm, and the length is 30-180mm(adjustable).

| Model | SL-320 | SL-450 |

| Capacity | 20-80bags/min | 20-80bags/min |

| Packing weight | ≤200g | ≤600g |

| Power | 1.8kw | 2.2kw |

| Bag style | Back seal or 3-side seal | Back seal or 3-side seal |

| Size | 650*1050*1950mm | 750*750*2100mm |

| Weight | 250kg | 420kg |

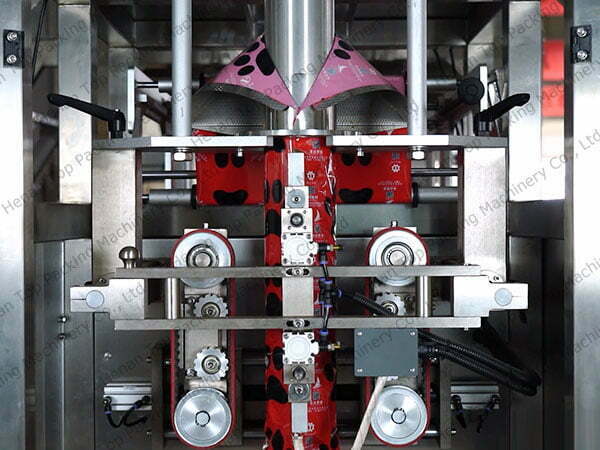

Structure of granule packing machine

Shuliy automatic rotary pouch granule packing machine is made of hopper, volumetric cups, control panel, bag former, sealing and cutting device, etc. In addition, this machine can equip the date printer.

The structure details are shown below for your reference to better understand the machine components.

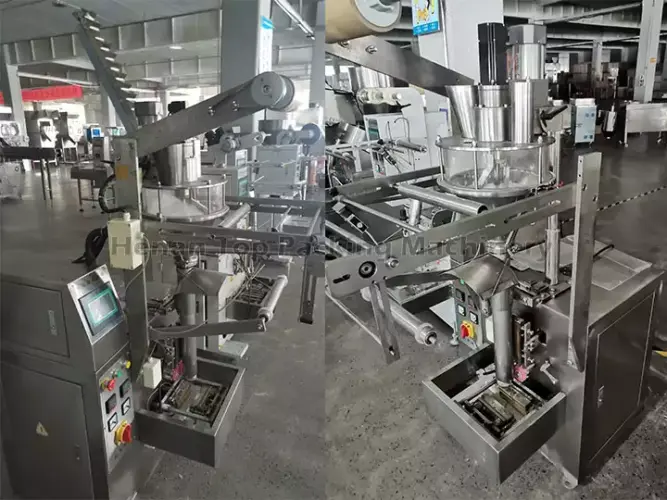

Type 2: chain bucket packing machine

SL-420 chain bucket packaging machine

This granules pouch packing machine can pack 30-60 bags per minute. Its packing weight has a range of 100-1000ml.

The packing style can be 4-side seal, 3-side seal and back seal.

It can automatically complete a series of actions including bag making, filling, counting, sealing and cutting finished products.

| Model | SL-420 |

| Capacity | 30-60bags/min |

| Max. film width | 430mm |

| Bag length | 30-280mm |

| Voltage | 220/380V |

| Total power | 1.2kw |

| Max. outer diameter of roll paper | ≤Φ350mm |

| Packaging film thickness | 0.03-0.10mm |

| Measuring range | 100-1000ml |

| Machine weight | 400kg |

| Machine size | 870*1350*1850mm |

Components of chain bucket granule packing equipment

This machine structure is easy. It’s composed of touch screen, hopper, film shaft, bag former, wheels, etc. If you want to know more, contact us now for more details!

Type 3: multi-head weighed packing machine

Multi-head weighing and packing machine

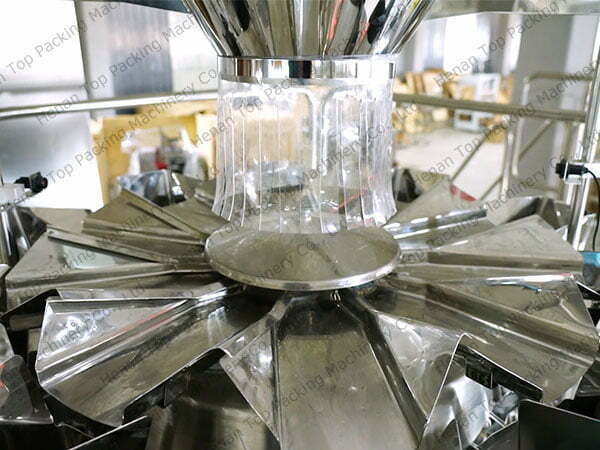

This machine is composed of multi-head weigher, automatic packing unit, Z elevator, and working platform.

It has an output of 5-50 bags per minute, and the packing weight is 150-6000ml.

The bag style can be a pillow-type bag, standing bag, punch, etc. It can be single bag or multi bags.

There are many kinds of multihead weighers for you to choose from. Some are listed for your reference.

| Multi-head weigher | 2-head weigher 4-head weigher 10-head weigher 14-head weigher |

Parameters for automatic packing machine used for multi-head weighing packing machine

| Model | SL-420 | SL-520 | SL-720 |

| Bag length | 80-300mm | 80-400mm | 100-400mm |

| Bag width | 50-200mm | 80-250mm | 180-350mm |

| Film width | 420mm | 520mm | 720mm |

| Packing speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Measuring range | 150-1200ml | Max. 3000ml | Max. 6000ml |

| Voltage | 220V | 220VAC/50HZ | 220VAC/50HZ |

| Power | 2.2kw | 4kw | 5kw |

| Dimension | 1320*950mm*1360mm | 1150*1795*1650mm | 1780*1350*1950mm |

| Machine weight | 540kg | 600kg | / |

If you want to use this fully automatic granule packing machine, choose a multi-head weigher and matched automatic packing machine unit. Get in touch with us for more details!

Main parts of multi-head weigher packing machine for particles

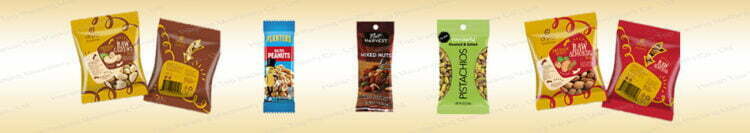

Granular products suitable for automatic granule packaging machine

Our granule packing machine has a wide range of applications, such as:

Nuts, grains, chocolates, puffed food, tea, potato chips, banana chips, snacks, chocolate, rice, popcorn, candy, sugar, shrimp strips, peanuts, soybeans, melon seeds, sunflower seeds, monosodium glutamate, corns, jelly, salt, cereal mix, plastic pellets, fertilizers, pills, vitamins, and so on.

With reasonable design and advanced structure, the granule packaging machines can finish automatic measuring, filling, bag-making, expiration date printing, and product output at one time. It’s convenient and cost-saving.

The bag style is various, like punch, stick, sachet, forked corners, back seal, 3-side seal, 4-side seal, etc.

We have different packing materials available, for example,

Polyester/aluminizing/Polyethylene, polypropylene/polyethylene aluminum foil/Polyethylene, nylon/Enhanced polyethylene, tea-leaf filtering paper, paper/Polyethylene, etc.

Features of the granule packing equipment

- It can automatically complete bag-making, measuring, feeding, filling, sealing, cutting, counting, and printing, and can increase the function of easy tearing.

- The granules pouch packing machine is made of 304 stainless steel, dural and long service life.

- With an advanced PLC control system and a 5-inch color touch screen, one worker is enough to operate it.

- The bag style can be back seal, 3-side seal and 4-side seal.

- Shuliy granules packaging machine has wide applications, like rice, sugar, beans, tea, chips, etc.

- We can customize the machine’s power, voltage, appearance, etc. to fit your business.

How does Shuliy granule packing machine work?

The working process of the granular packing machine is mainly divided into the following steps:

- Material placing

- First, put the granular material to be packed into the hopper.

- Metering

- Our granule packaging machine weighs the material accurately using a dosing device.

- Bag forming

- After weighing, the machine automatically prepares the bags. Usually, the machine cuts a certain length of film material from the roll to form a bag.

- Filling

- The dosed material passes through the filling port into the prepared bag. This process ensures that the material is accurately filled into the bag.

- Sealing

- Once the filling is complete, the machine automatically seals the bag. Generally, heat sealing technology is used to seal the open part of the bag to ensure the safety and freshness of the material.

- Cutting and discharging

- Finally, the machine cuts the film at the sealing area and discharges the packaged product automatically.

What is the granule packing machine price?

Shuliy granule packaging machine price is closely related to lots of factors, such as material, transportation cost, tax cost, parameters, etc. Every factor can greatly affect the granule packing equipment cost.

For example, the shipping cost increases hugely, and the cost of the packing machine increases. And large packing machine cost is more expensive than small packing machine cost.

If you want to know the granules pouch packing machine price, please contact us, and we can give you the best quotation.

How to maintain a granule packaging machine?

- Regular inspection of components

- Regularly check the machine parts to ensure that they rotate flexibly. Repair defects when found to avoid affecting the normal operation of the machine.

- Cleaning after downtime

- When the machine is stopped for a long time, the whole machine needs to be wiped to keep it clean.

- Pay attention to the electrical parts

- The electrical parts should pay attention to waterproof, moistureproof and anti-corrosion. Make sure the electric control box and terminals are kept clean to avoid electrical failure.

- Common troubleshooting

- Common problems of the automatic rotary pouch granule packing machine include malfunctioning of the control panel, weighing system or filling mechanism. You should troubleshoot these problems on time.

Why use an automatic granule packaging machine?

There are numerous advantages to using Shuliy granular packing machine, including:

- Increase speed and accuracy of packing.

- The machine can significantly increase the speed and accuracy of the packing process, resulting in improved efficiency and productivity.

- Improve consistency and uniformity of packed products.

- Our machine can improve the consistency and uniformity of packed products.

- Reduce labor and material costs.

- It can reduce labor and material costs.

Granule pouch packing machine manufacturers from China

As one of the leading granule packaging machine manufacturers in China, our products are highly competitive both in quality and price.

- Firstly, we have rich experience in the design, research, manufacture, and marketing of packaging machines. We have established a mature supply chain system and quality control system.

- Secondly, factory-direct features make our product more competitive. Our granule packaging equipment price is more favorable than many other packing machine manufacturers.

- Thirdly, Shuliy has a strong capability to offer OEM service to accurately fit your special needs.

Get in touch with us for the best price!

Are you looking for packing equipment for granulars? Contact us today for more information and the best prices.