Shrink packing machine

| Brand | Shuliy |

| Packing speed | 15-30pcs per minute |

| Packing capacity | 0-30pcs/min |

| Sealing temperature | 140-180℃ |

| Heat shrinking temperature | 0-300℃ |

| Suitable shrink film | POF, PVC, PE |

| Applications | Gift box, book, sushi box, hardware parts box, cosmetic, mask box, kitchenware, etc. |

Shuliy shrink packing machine makes the shrink film tightly stick to the product appearance through high temperature hot air to realize the effect of beautiful, dust-proof, moisture-proof and sealed packaging. It’s widely used in food, beverage, daily necessities, hardware tools, electronic products, books, cosmetics and other industries.

This shrink wrapping machine has a packing speed of 15-30 pcs per minute, the sealing temperature is 140-180℃, and the shrinking temperature is 0-300℃. The applicable shrink film has POF, PVC, PE, etc.

Are you interested in it? Welcome to contact us for more details!

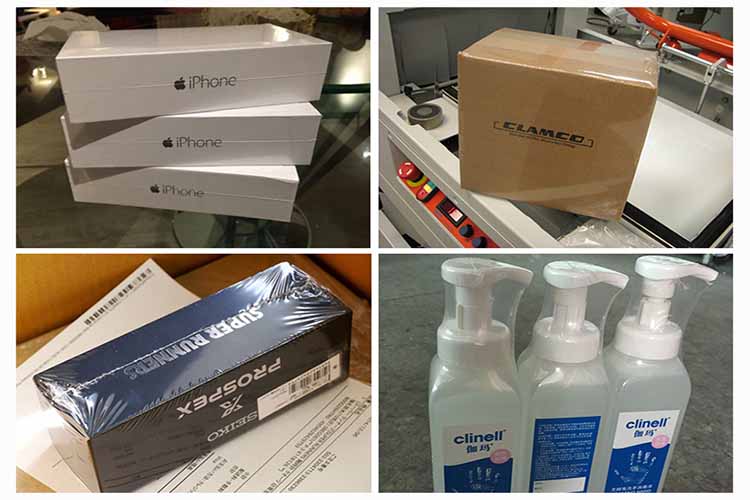

Wide applications of automatic shrink packing machine

Our heat shrink machine is suitable for all kinds of objects packaging, having a wide range of applications, such as:

- Individual products

- Books and stationery: books, hardcover notebooks, magazines, postcards, and stationery sets.

- Daily commodities: toothpaste, toothbrushes, shampoos, shower gels, hair dyes, etc.

- Daily necessities: masks, dishes, wood products, small appliances (such as rice cookers), toys, etc.

- Cosmetics: skincare products in boxes, color cosmetics sets, etc.

- Pharmaceutical products: over-the-counter drug boxes, health care bottles, medicines, etc.

- Combination packaging

- Family sets: toiletries sets, toothpaste + toothbrush sets, kitchen sets.

- Stationery gift box: notebook + pen combination, school supplies multi-packs.

- Cosmetic sets: such as toiletries three-piece set, mask set, travel suit gift box.

- Toy sets: puzzles, blocks, small toy series packaged for sale.

- Products with tray

- Wholesale transportation of daily necessities: such as toothpaste whole box, shampoo whole tray.

- Wholesale distribution of books: the whole box of hardcover books packaged for shipment.

- Supermarket/super distribution: paper towels, shower gel, tableware bulk transportation packaging.

- Industrial products: wood products, large quantities of hardware, and whole pallet packing shipment.

Features of heat shrink packing machine

- The machine can automatically finish the process of plastic wrapping, sealing, cutting, and shrinking.

- This shrink wrap machine supports shrink films like POF, PVC, PE, etc., for packing.

- The heating knife is equipped with a heat-insulating cloth to avoid direct contact with the film.

- The temperature ranges 0-300℃, and the proper temperature is determined according to the film thickness.

- It gives the product a neat appearance to enhance the product grade. The shrink film is close to the product surface, better display effect.

- Our machine can make products moisture-proof, dust-proof, and tightly encapsulated, extending the shelf life of the product and making it conducive to storage and transportation.

- We can customize the power cable length, plugs with American standards or European standards, machine cover, etc.

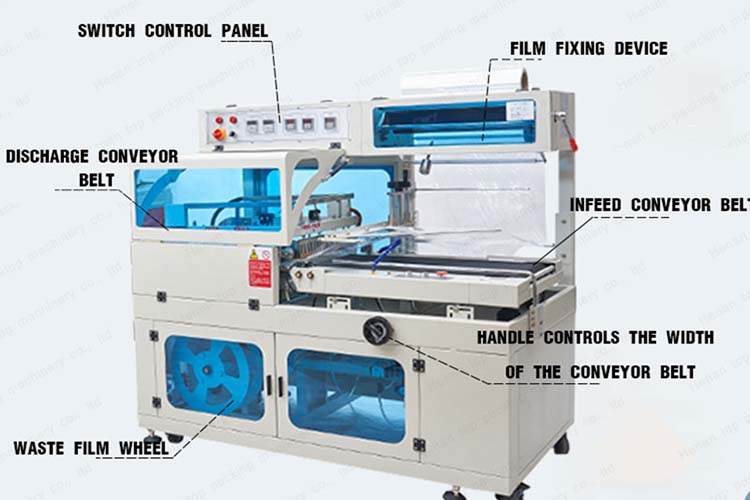

Automatic heat tunnel shrink packing machine structure and parameters

This shrink wrap machine consists of a L-sealing and cutting machine and a shrink wrapping tunnel machine.

Automatic L sealer

The L sealer machine structure includes control panel, film fixing device, feeding conveyor belt, handle control, waste plastic film wheel, output conveyor belt, etc.

- Control panel: set up vertical and horizontal sealing temperature, the time of sealing and cutting, the start button, etc.

- Film fixing device: prick some small holes on the film surface to facilitate exhausting the air in the bag during the shrinking process.

- Triangle plate: stretch the film smoothly, easy to see the position of the film.

- Waste plastic film wheel: roll the waste film around the wheel automatically.

Automatic film sealing and cutting machine parameters

| Model | SL-450L | SL-550L | SL-750L | |

| Voltage | 220V/50-60HZ | 220V/50-60HZ | 220V/50-60HZ | |

| Power | 1.6kw | 1.86kw | 2.26kw | |

| Packing capacity | 15-30pcs/min | 15-30pcs/min | 15-30pcs/min | |

| Air pressure | 0.5Mpa | 0.5Mpa | 0.5Mpa | |

| Max. packing size | L+2H≤550mm, W+H≤35mm, H≤140mm OR W+H≤400 L+H≤50 H≤150mm | W+H≤500 L+H≤60 H≤150mm | W+H≤700 L+H≤80 H≤150mm | |

| Cutter size | 570*470mm | 670*570mm | 870*770mm | |

| Sealing temperature | 140℃-180℃ | / | / | |

| Thickness of film | 0.015-0.1mm | / | / | |

| Shrink film | POF, PVC, PE | POF, PVC, PE | POF, PVC, PE | |

| Machine size | 1700*880*1470mm | 1900*1100*1500mm | 2250*1180*1475mm | |

| Outside packing size | 1760*1010*1620mm | 1960*1200*1610mm | 2350*1350*1630mm | |

| Conveyor width | 330mm | 430mm | 600mm | |

| Weight | 291kg | 334kg | 440kg |

Heat shrink tunnel machine

It includes control panel, shrink furnace, conveyor belt resistant to high temperature, conveyor motor, heating pipes, fan, etc.

- Control panel: set up the total power switch, hot wind switch, heating switch, carry switch, carry adjust, temperature control, etc.

- Heat tunnel: its interior has heating pipes on both sides.

- Fan on the top side of the furnace: work to circulate the hot air in the machine, making the internal temperature more even.

Industrial shrink tunnel wrapping machine parameters

| Model | SL-4522 | SL-5530 | SL-7535 |

| Voltage | 220-380V/50-60HZ | 220V/50-60HZ | 220V/50-60HZ |

| Power | 15kw | 16kw | 24kw |

| Conveying speed | 0-15m/min | 0-16m/min | 0-15m/min |

| Temperature control | 0-300℃ | 0-300℃ | 0-300℃ |

| Machine size | 1900*710*1260mm | 1900*810*1320mm | 2200*1010*1420mm |

| Tunnel size | 1500*450*220mm | 1500*550*300mm | 1800*750*350mm |

| Conveyor loading | 20kg | 20kg | 40kg |

| Suitable shrink film | POF, PVC, PE | POF, PVC, PE | POF, PVC, PE |

| Outside packing size | 2000*810*1480mm | 2000*910*1550mm | 2280*1080*1640mm |

| Weight | 200kg | 230kg | 336kg |

Cautions of industrial shrink packing machine

- Read the operation manual before use based on the safety considerations.

- Do not put your hands near it when the machine is in operation.

- The shrink wrap machine must keep the ground wire connected.

What’s the shrink packing machine price?

The price of our shrink wrapping machine is usually determined by the following factors:

- Packaging size and output requirements

- Larger size or high-speed production line price is higher.

- Configuration differences

- Whether you need a fully automatic sealing and cutting machine, whether it supports uninterrupted operation, whether there is an intelligent temperature control system and so on.

- Matching equipment

- Such as automatic loading system, printer, labeling machine, etc., the whole line is smarter but more costly.

Want to know the exact price of the heat shrink machine? Welcome to contact us to provide product specifications, packaging forms, we will be tailored to recommend the most cost-effective model program.

Why choose Shuliy heat shrink packaging machine?

As a professional manufacturer and supplier of packaging machines, our equipment is very popular in the market, mainly due to the following attractions:

- Multiple models to choose from

- Factory direct sale, affordable price

- Support customized solutions

- Experienced in export

- Worry-free after-sales and professional service

In addition to the above equipment, we also have pillow packing machine, granule packing machine, powder packing machine for sale.

Are you looking for a suitable packaging machine? Contact us, tell us your items such as books, kitchen utensils or others, and we will recommend the most suitable packaging machine for you according to your needs.