Electric vertical packing machine

Electric vertical packing machine mainly consists of two parts, feeding system, and packaging system. The feeding system is a small filling machine for powder, granule, or two-in-one. Many filling scopes are optional. The packaging system is used to make bags to package falling materials from the feeding system. Compared with a standard granule or powder packing machine, the machine fills higher precisely by quantitative weighing, but packaging speed is slower. And it’s low cost, suitable for small and medium businesses. Besides, customization service is available according to your needs.

Electric vertical packaging machine for sale

Electric vertical packing machine in Henan Top Packing machinery for sale includes electric side seal type packaging machine and electric back seal type packaging machine. The two types of equipment are different in bag maker, vertical sealing device, and end sealing and cutting device. The machine can make 3-side seal bags or back seal bags. It can separately finish the process of weighing, bag forming, filling, sealing, and cutting. The control panel can set up sealing temperature and bag length, and display upper temperature, lower temperature, and actual length.

Features of electric vertical packaging machine

- Reasonable design, simple structure, easy to operate

- Accurate weighing, high precision, low cost, affordable price

- Many packaging scopes can be chose based on your needs

- 3-side seal bag, and back seal bag are optional

- Customization service available

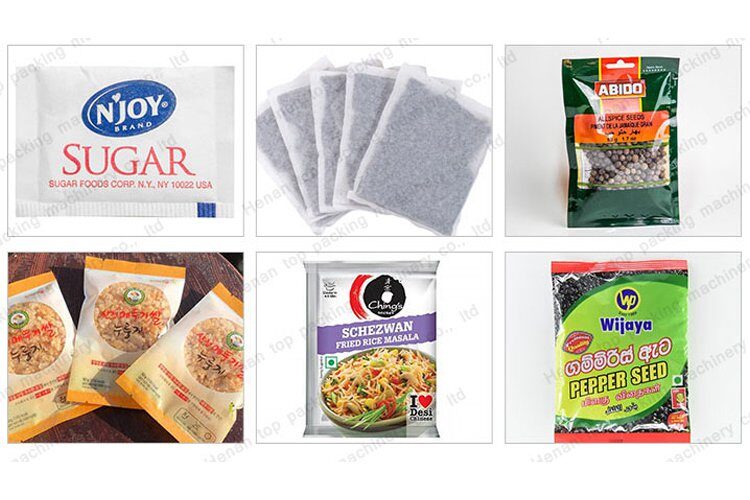

Wide applications of small electric packing machine

The machine is similar to other granule packing machines and powder packaging machines. It applies to various granules and powder, such as peanut, coffee bean, melon seeds, grains, nuts, oatmeal, rice, tea, dried fruit, sesame, soybean, green bean, red bean, monosodium glutamate, salt, flour, milk powder, cornflour, rice flour, coffee powder, spice, chili powder, starch, dyes powder, detergent powder, etc.

Electric vertical form filling sealing machine working video

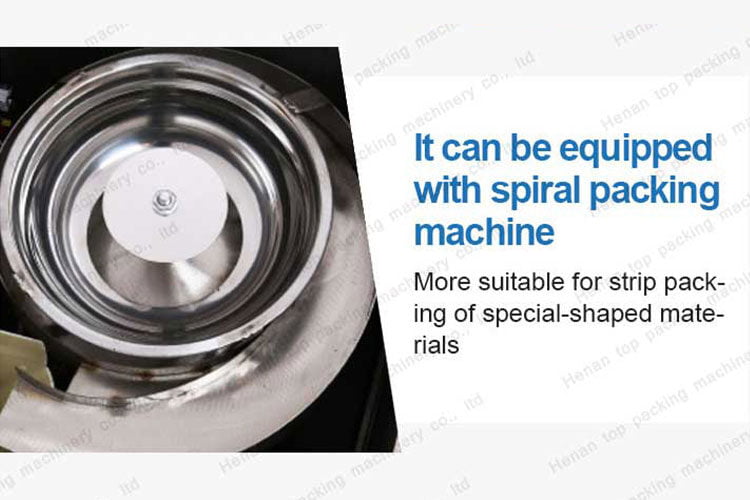

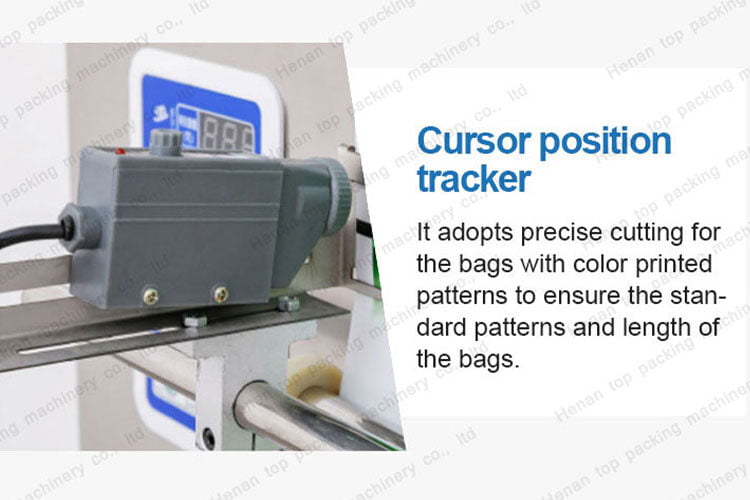

Electric vertical packing machine structure

The electric packing machine is a kind of vertical form fill seal machine. It is composed of packaging roll film, material hopper, quantitative control panel, bag former, encapsulated control panel, power switch, separator, sealing device, packaging film pulling wheels, discharge hole. It adopts quantitative weighing and filling, highly precise and accurate. The intelligent control panels can set up various parameters about filling and packaging, which is simple to operate. Bag maker is used for shaping bags for packaging. The heating seal is stable and good effect. Packaging film pulling wheels draw film downward, promoting packaging efficiency. Besides, the machine also can match with other devices, such as a date printer, loading device, nitrogen filling device, etc.

Detailed components of the electric vertical packer

Electric side seal vertical packaging machine parameters

| Model | CF-200 | CF-260 | CF-300 |

| Power | 600W | 700W | 800W |

| Packaging speed | 700-1200 bags/h | 650-1000 bags/h | 650-1000 bags/h |

| Packaging film width | 5-20cm | 21-26cm | 27-30cm |

| Bag length | 3-17cm | 3-22cm | 3-22cm |

| Machine size | 45*55*148cm | 56*63*168cm | 56*63*168 |

Electric back seal vertical packaging machine parameters

| Model | BF-200 | BF-260 | BF-340 | BF-440 |

| Power | 600W | 700W | 800W | 900W |

| Packaging speed | 700-1200 bags/h | 650-1000 bags/h | 650-1000 bags/h | 600-950 bags/h |

| Packaging film width | 5-20cm | 21-26cm | 27-34cm | 35-44cm |

| Bag length | 3-17cm | 3-22cm | 3-22cm | 5-27cm |

| Machine size | 45*55*148cm | 56*63*168cm | 56*63*168cm | 66*77*180cm |

Conclusion

The electric vertical packing machine can automatically finish the packaging process. Its working speed is slower than a standard granule packer and powder packer, but its filling precision is higher because the machine adopts quantitative weighing and filling, rather than measuring cups or anger. Besides, it also has advantages of low cost, affordable price, suitable for small and medium businesses. If you want to get more details or to be a distributor, you can contact us and we will reply to you as soon as possible.