What Is A Bagging System?

A bagging system is a packaging solution that automates the process of filling and sealing bags or pouches with various products. It typically involves a combination of equipment and machinery designed to efficiently package goods in a systematic and controlled manner. Bagging systems are commonly used in industries such as food, pharmaceuticals, agriculture, and manufacturing, where high-volume packaging is required. These systems offer numerous benefits, including increased productivity, reduced labor costs, improved packaging accuracy, and enhanced product protection.

Components of a Bagging System

A typical bagging system consists of the following components:

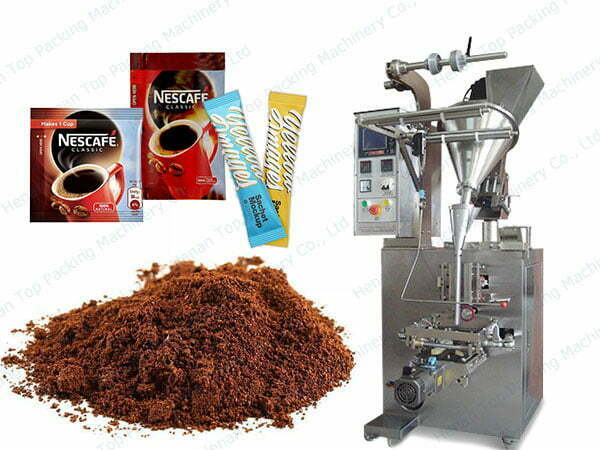

- Bagging Machine: The core component of the system, the bagging machine, is responsible for the automatic filling and sealing of bags. It may include features such as hoppers, conveyors, weighing scales, and filling mechanisms tailored to specific product requirements.

- Bag Feeding System: This component ensures a steady supply of empty bags to the bagging machine. It can involve mechanisms like bag magazines, rotary bag loaders, or continuous bag feeding systems that efficiently deliver bags to the filling station.

- Product Delivery System: The product delivery system transports the goods to be packaged from the production line to the bagging machine. It can involve conveyors, chutes, or feeders that control the flow of products and ensure accurate filling.

- Weighing or Measuring Devices: In many bagging systems, weighing or measuring devices are incorporated to ensure the precise filling of the bags. These devices can include scales, volumetric fillers, or counting mechanisms that measure or weigh the product before it is dispensed into the bags.

- Bag Sealing and Closure: Once the bags are filled with the desired quantity of product, a sealing mechanism is employed to close and secure the bags. This can be achieved through heat sealing, ultrasonic sealing, zip-lock closures, or other sealing methods, depending on the bag type and product requirements.

- Controls and Automation: Bagging systems often feature sophisticated control systems that allow operators to program and adjust various parameters such as bag size, filling quantity, speed, and sealing temperature. Automation capabilities ensure consistent and reliable packaging results.

Benefits of Bagging Systems

Bagging systems offer several advantages over manual packaging methods. Some key benefits include:

- Increased Productivity: Bagging systems automate the packaging process, significantly increasing production speed and output. They can handle high volumes of products, allowing for faster packaging and reduced labor requirements.

- Improved Packaging Accuracy: By utilizing precise weighing or measuring devices, bagging systems ensure consistent and accurate product quantities in each bag. This reduces product giveaways and enhances quality control.

- Enhanced Product Protection: Bagging systems provide a secure and sealed packaging solution, protecting products from contaminants, moisture, and other external factors that may compromise their quality or shelf life.

- Cost Savings: Automation in bagging systems reduces labor costs and increases operational efficiency, leading to overall cost savings for manufacturers. Additionally, optimized material usage and reduced product waste contribute to cost-effectiveness.

- Versatility and Flexibility: Bagging systems can accommodate a wide range of products, from powders and granules to liquids and solids. They can handle different bag sizes, types, and closures, allowing for versatility in packaging applications.

- Consistency and Standardization: Bagging systems ensure consistent packaging results, reducing variations in bag size, weight, and sealing. This improves the overall visual appeal and marketability of the packaged products.

In conclusion, a bagging system automates the process of filling and sealing bags or pouches, providing numerous benefits to manufacturers. With their efficiency, accuracy, product protection, and cost-saving capabilities, bagging systems have become essential equipment in various industries, streamlining packaging operations and ensuring the delivery of high-quality products to consumers.

A bagging system is highly important for a packaging machine. It is an indispensable part of it. Founded in 1993, we are a leading packing machine factory and supplier. We provide a full range of packaging solutions for various food and non-food products. If you want to know more about the bagging system, contact us for more useful information.