Order hookah charcoal packing machine for UAE charcoal manufacturer

The UAE client is a specialized shisha charcoal manufacturer with long-term exports to Middle Eastern, European, and African markets. As overseas demand grew, traditional manual packaging methods could no longer meet large-volume order requirements. The client particularly sought solutions for:

- Enhance production efficiency to fulfill large order delivery demands

- Achieve aesthetically consistent packaging for entry into supermarkets and export markets

- Reduce reliance on manual labor and increase automation levels

Customer requirements analysis

This client primarily manufactures round hookah charcoal and requires a hookah charcoal packing machine capable of handling various bag specifications while maintaining high-speed operation and stable performance. Core requirements include:

- Packaging speed: Suitable for large-scale production, with a single machine speed of approximately 200 bags per minute.

- Packaging specifications: Bag length of 65–190mm or 120–280mm, and bag width of 30–110mm.

- Equipment characteristics: High automation, stable operation, moderate footprint, and seamless integration into factory assembly lines.

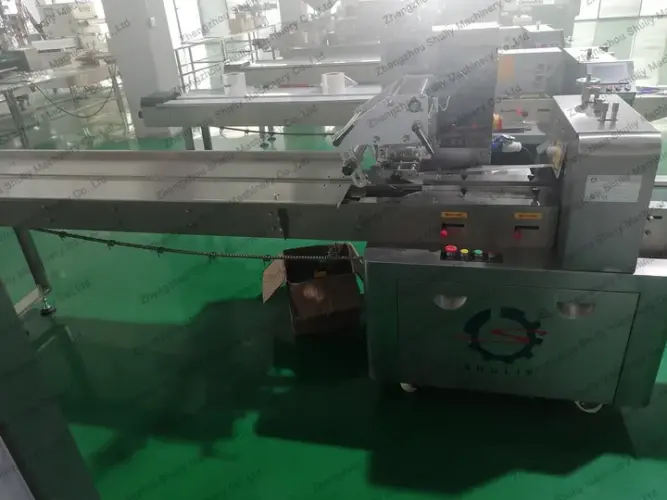

Shuliy solution

Based on the client’s requirements, we recommended and supplied a fully automatic hookah charcoal packaging machine. This equipment features:

- High-speed packaging capacity: Capable of completing 40-330 bags per minute, significantly boosting production efficiency.

- Multi-specification adaptability: Flexible adjustment of bag length and width to meet diverse export market demands.

- Automatic operation: This hookah charcoal packing machine integrates automatic feeding, metering, bag forming, filling, and sealing, greatly reducing manual intervention.

| Machine name | Parameters | Qty |

| Pillow packaging machine for round shisha charcoal | Bags length: 65-190mm or 120-280mm Bags width: 30-110mm Speed: 40-330bags/min Dimension: 3770*670*1450mm Weight: 800kg | 1 set |

Key collaboration points

Throughout the collaboration, we maintained close communication with the client:

- Preliminary research

- Customized machine recommendations based on the client’s circular hookah charcoal specifications and export market packaging requirements.

- Production testing

- Demonstrated packaging results via trial operation videos to ensure aesthetically consistent finished products.

- After-sales support

- Provided operational training and remote technical guidance to ensure the client team could quickly master the hookah charcoal packing machine.

Application outcomes

Following the implementation of our hookah charcoal packing machine, the client successfully addressed issues of low manual efficiency:

- Production efficiency boost: Packaging speed increased nearly threefold, fully meeting large export orders.

- Consistent product quality: Aesthetically pleasing and uniformly packaged bags enhanced brand image.

- Strengthened export competitiveness: Products gained easier access to major supermarket channels in the Middle East and Europe.

If you’re looking for a suitable packaging machine for charcoal, please feel free to contact us. We’ll recommend the right equipment for your needs.