Mashine ya kujaza kioevu

Mashine ya kujaza kimiminika ni aina moja ya mashine ya kujaza kiwango, kujaza kwa usawa, rahisi kufanya kazi. Kifaa kinafaa kwa aina mbalimbali za vimiminika ambavyo hutiririka vizuri, kama vile maji, juisi, maziwa, divai, bia, pombe, siki, kinywaji, mafuta, kilainishi, maji ya vipodozi, n.k. Aina mbalimbali za miundo ya pampu za kujaza kimiminika zinapatikana kwa hiari. Unaweza kuchagua kifaa cha kujaza kinachofaa zaidi kulingana na mahitaji yako kuhusu kiasi unachotaka kujaza. Kwa kuongezea, tunasaidia pia huduma ya ubinafsishaji kulingana na mahitaji yako halisi.

Mashine ya kujaza kioevu inauzwa

Kuna aina mbili za mashine za kujaza kioevu kwenye Mashine ya Ufungashaji ya Juu (Henan) ya kuuza, kichungi cha kioevu cha otomatiki moja kwa moja, na kichungi cha kioevu cha vichwa vingi. Ya kwanza ina faida za gharama ya chini, sehemu ndogo iliyokaliwa, na matumizi pana, yanafaa kwa biashara ndogo. Mashine za mwisho na zingine zinaweza kutunga laini ya uzalishaji wa ufungaji wa kioevu, kama mashine ya chupa isiyo na kichanganyiko, mashine ya kuweka alama, mashine ya kuweka lebo, printa ya kuweka misimbo, n.k., inafanya kazi kwa ufanisi na kwa usahihi, inayofaa kwa utengenezaji wa kujaza kioevu kwa wingi.

Mashine ya kujaza kioevu ya nusu-otomatiki moja kwa moja

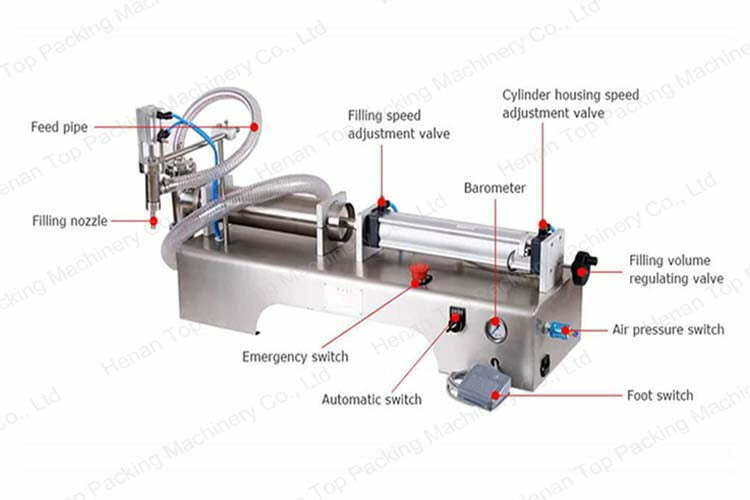

Mashine ya kujaza kioevu ya sehemu moja ni mashine ya kujaza bastola ya nusu-otomatiki, inayoendeshwa na silinda ili kutoa na kutoa vifaa. Mwili wa mashine umeundwa kwa chuma cha pua, kinachodumu, na ni rahisi kusafisha na kutunza. Kiwango kiko kwenye kifaa ili kurekebisha kiasi cha kujaza, rahisi kufanya kazi. Saizi nyingi za pampu za kioevu ni za hiari. Upeo wa mifano ya pampu ya kujaza ni pamoja na 1-10ml, 10-100ml, 100-1000ml, 5-50ml, 50-500ml, 500-5000ml, 3-30ml, 30-300ml, 300-500ml nk, 300ml nk. unaweza chagua kulingana na mahitaji yako. Mashine hiyo ni maarufu kwa biashara ndogo ndogo kwa sababu ya tabia yake ya nafasi ndogo iliyochukuliwa, ubora mzuri, na gharama ya chini.

Muundo wa mashine ya kujaza kioevu kwenye sehemu moja

Vifaa vya kujaza kioevu vya vichwa vingi vya moja kwa moja

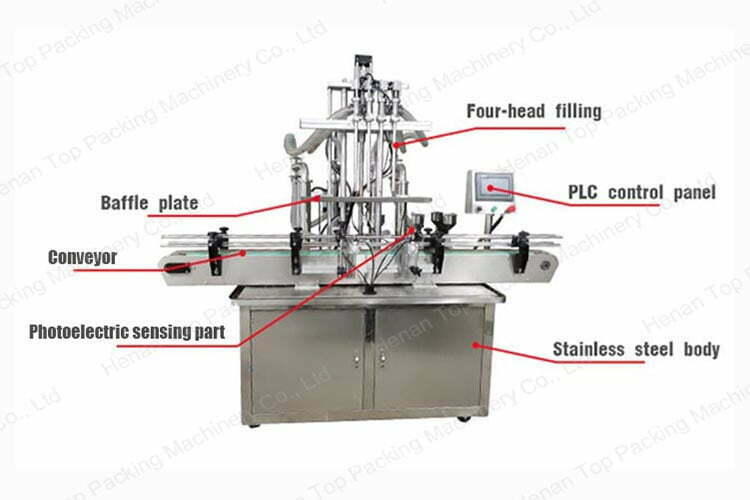

Kichujio cha kioevu cha vichwa vingi kiotomatiki, kama jina linamaanisha, inachukua vichwa vingi vya kujaza, na kuboresha sana uzalishaji wa kufanya kazi. Miongoni mwao, vifaa vya kujaza kioevu vya kichwa 12 vinaweza kufikia chupa 3000 / h. Idadi ya chini ya vichwa vya kujaza ni mbili, na nambari inaweza kubinafsishwa. Unaweza kuchagua kulingana na kiwango chako cha uzalishaji. Mbali na hilo, kifaa cha kichwa cha kujaza mstari kina vifaa vya kupambana na matone kuzuia upotevu wa vifaa. Mifano ya pampu ya upeo wa kujaza ni 10-100ml, 50-500ml, 100-1000ml, 500-3000ml, 1000-5000ml, nk Matokeo yake ya kujaza ni sahihi na hata. Inaweza pia kuendana na mashine zingine ili kutunga laini ya uzalishaji, inayofaa kwa biashara za kati na kubwa.

Muundo wa mashine ya kujaza chupa yenye vichwa vingi

Vipengele na faida za mashine za kujaza kioevu

- Ubunifu wa busara, muundo rahisi, kujaza kwa kiasi, rahisi kufanya kazi

- Upeo mbalimbali wa pampu ya kujaza kioevu kwa hiari, kiasi cha kujaza na kasi hurekebishwa

- Mwili wa kifaa huchukua chuma cha pua, cha kudumu na rahisi kusafisha na kudumisha

- Ina kifaa cha kuzuia matone ili kuhakikisha kujaza kwa usahihi.

- Kichungi cha kioevu cha nusu-otomatiki kinachukua nafasi ndogo, ina uwekezaji mdogo, kelele ya chini

- Kijazaji kiotomatiki cha vichwa vingi kinaweza kuendana na mashine zingine ili kutunga laini nzima ya uzalishaji, kutambua otomatiki kamili, kuboresha ufanisi, na kuokoa kazi.

- Haja ya kufanya kazi na compressor hewa pamoja

- Huduma ya ubinafsishaji inapatikana

Mashine ya kujaza chupa ya maji yenye vichwa vingi inayofanya kazi video

Maombi ya vifaa vya kujaza kioevu

Mashine za kujaza kimiminika zinafaa kwa kujaza kimiminika chenye utiririkaji mzuri, zinatumika sana kwa maji, vinywaji, viungo, mafuta, mahitaji ya kila siku, dawa, vipodozi, kemikali, viongezi, n.k. Kifaa kinaweza kujaza maji ya madini, maji ya soda, maji yanayometa, juisi, maziwa, bia, divai, siki, pombe kali, pombe, vimiminika vya mdomo, mafuta ya kula, mafuta ya zeituni, mafuta ya karanga, kilainishi, maji ya vipodozi, kimiminika cha kufulia, vitakasa mikono, shampoo, gel ya kuoga, dawa za kuua viini, antifreeze, dawa za kuua wadudu, dawa za kuua magugu, na kadhalika. Kwa kujaza kimiminika chenye mnato, unahitaji kutumia mashine ya kujaza kuweka.

Bei ya mashine ya kujaza kioevu

Bei ya kifaa cha kujaza kimiminika inahusiana na aina ya mashine, ukubwa wa pampu ya kujaza, idadi ya sehemu za kujaza, n.k. Ikilinganishwa na kifaa cha kujaza kimiminika cha sehemu moja cha nusu-otomatiki, bei ya kifaa cha kujaza kimiminika cha kichwa nyingi cha kiotomatiki ni ya juu kwa sababu cha mwisho kinahitaji gharama kubwa zaidi ya uzalishaji. Kwa ukubwa tofauti wa pampu za kujaza kimiminika, ile kubwa zaidi ni ghali zaidi. Kwa kuongezea, kuhusu kifaa cha kujaza kimiminika cha kichwa nyingi, vichwa vya kujaza zaidi pia vinahitaji gharama kubwa zaidi. Kama mtengenezaji na mtoaji wa vifungashio, tutafanya tuwezavyo kutoa mashine za utendaji wa gharama ya juu. Lakini kama msemo unavyosema, unapata kile unacholipa. Kwa hivyo ni vyema usipuuze ubora na sifa zingine kwa sababu ya bei. Wasiliana nasi kupata maelezo zaidi.