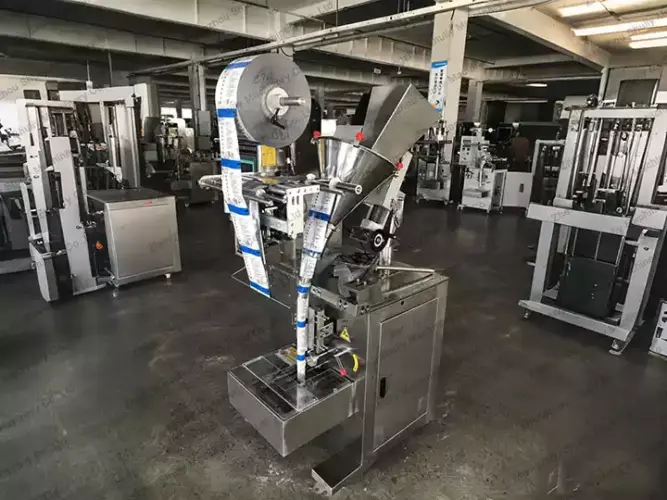

SL-320 kaon pola ya kitamu ya kitandikio imewekwa kwenye Congo DR

Mnamo Oktoba 2025, tulisafirisha mashine ya ufungaji wa unga wa kitunguu kwenda Jamhuri ya Kidemokrasia ya Kongo, ikimsaidia mteja kuboresha ufanisi wa ufungaji na muonekano ili kuongeza mauzo.

Asili ya mteja: Kiwanda cha usindikaji wa unga wa kitunguu cha eneo

Mteja huyu kutoka Jamhuri ya Kidemokrasia ya Kongo anafanya kazi kiwanda cha usindikaji kinachobobea na uzalishaji wa unga wa kitunguu, kikitoa kwa masoko ya ndani na wauzaji wakubwa. Kadri mauzo yalivyoongezeka, ufungaji wa mikono haukuweza kukidhi mahitaji ya agizo, mara nyingi kusababisha ukubwa usioendana wa ufungaji, kasi ndogo, na uvujaji wa unga.

Baada ya kufanya utafiti, mteja alibaini hitaji la mashine ya kitaalamu ya ufungaji wa unga wa kitunguu ili kufanikisha uzalishaji wa kiwango na ufanisi wa juu.

Mahitaji ya mteja na vigezo vya ufungaji

Mteja alibainisha mahitaji wazi ya ufungaji:

- Uzito wa ufungaji: 100g, 150g

- Ukubwa wa mfuko: 15cm × 14cm

- Upana wa filamu (Unfolded): 300mm

- Njia ya kufunga: Kufunga nyuma

Hizi specifications zinaendana kikamilifu na safu ya usindikaji ya SL-320 Mashine ya ufungaji wa unga, ikiruhusu usahihi wa kupimia, uundaji wa mfuko wa haraka, na ufungaji wa nyuma safi na wa kupendeza.

Suluhisho la Shuliy na mashine ya ufungaji wa unga wa kitunguu

Kwa kuzingatia muundo mzuri wa unga wa kitunguu na mwelekeo wa kuzalisha vumbi, tulipendekeza mashine ya ufungaji wa unga wa SL-320 iliyo na mfumo wa kupimia kwa shaba. Mfano huu una sifa za:

✅Mfumo wa kupimia wa usahihi wa juu unaothibitisha upungufu mdogo wa uzito wa kujaza (100–150g)

✅Mfumo wa kuunda mfuko wa thabiti unaolingana na upana wa filamu wa 300mm

✅Muundo wa kufunga nyuma wa kupendeza na salama unaoboreshwa kwa uwasilishaji wa bidhaa

✅Uendeshaji wa moja kwa moja unaopunguza gharama za kazi kwa kiasi kikubwa

Pia tulitoa mapendekezo ya muundo wa kuzuia kuziba kulingana na sifa za unga wa kitunguu, kuhakikisha uendeshaji wa mashine wa muda mrefu na thabiti.

Agizo la mwisho na maoni ya mteja

Baada ya kuthibitisha suluhisho, mteja alitoa agizo la mashine 1 ya ufungaji wa unga wa SL-320 kwa ajili ya sehemu ya unga wa kitunguu.

Baada ya mashine ya ufungaji wa unga wa kitunguu kuanza kazi, kasi ya ufungaji na ubora wa muonekano viliboreshwa sana, na kufanya iwe rahisi kwa bidhaa kuingia kwenye masoko ya ndani na masoko ya jumla. Mteja alionyesha kuridhika sana na anapanga kupanua mstari wa uzalishaji wa unga wa kitunguu na kuendelea na ushirikiano siku zijazo.