आलू के चिप्स को कुरकुरा रखने के लिए उनकी पैकेजिंग कैसे करें?

आलू के चिप्स आलू से बने एक प्रकार के स्नैक को संदर्भित करते हैं और कई देशों में स्नैक बाजार का एक महत्वपूर्ण हिस्सा हैं। यदि आलू के चिप्स को लंबे समय तक ऑक्सीजन के संपर्क में रखा जाए, तो उनमें बड़ी संख्या में फैटी एसिड ऑक्सीकृत हो जाएंगे, जिससे उनका स्वाद खराब हो जाएगा। हवा में नमी न केवल आलू के चिप्स को नम और मुलायम बनाएगी बल्कि बैक्टीरिया भी आसानी से पनपने का कारण बनेगी। इसलिए, आलू के चिप्स के बैग को आमतौर पर नाइट्रोजन गैस से भरने की आवश्यकता होती है, जो न केवल कुरकुरा और ताजा स्वाद बनाए रख सकता है बल्कि चिप्स को प्रभावी ढंग से टूटने से भी बचा सकता है। क्या आप जानते हैं कि आलू के चिप्स कैसे पैक किये जाते हैं? आज हम इसके बारे में विस्तार से जानेंगे।

आलू चिप पैकिंग मशीन कैसे काम करती है?

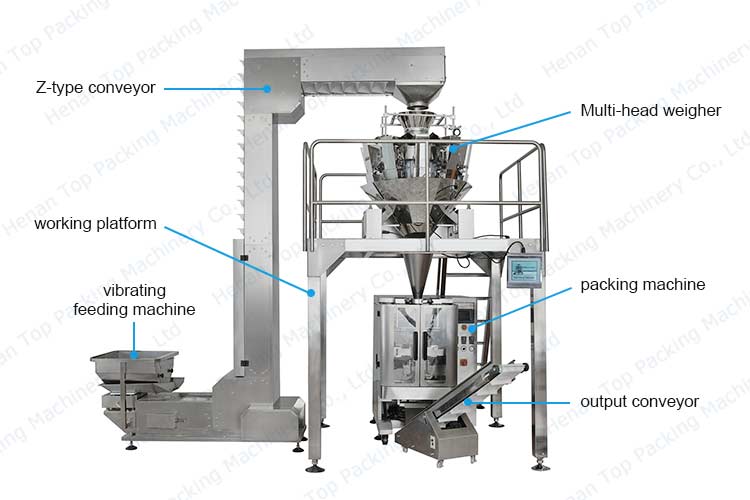

मल्टी-हेड कॉम्बिनेशन वेटर आलू चिप्स पैकेजिंग उपकरण आमतौर पर नाइट्रोजन फिलिंग डिवाइस, जेड-टाइप कन्वेयर, वर्किंग प्लेटफॉर्म और आउटपुट कन्वेयर से मेल खाता है। Z-प्रकार का कन्वेयर एक वाइब्रेटिंग फीडिंग मशीन और सामग्री पहुंचाने के लिए बहुत सारी बाल्टियों से सुसज्जित है। चिप्स को फीडिंग मशीन में डालने के बाद यह वाइब्रेटिंग के जरिए एक-एक करके चिप्स को बाल्टियों में भर सकता है। इन चिप्स को मल्टी-हेड वेइगर में ले जाया जाएगा। संयोजन तराजू सामग्रियों को कुशलतापूर्वक और सटीक रूप से तौलते हैं। फिर मल्टी-हेड वेगर आलू के चिप्स को पैकेजिंग बैग में डाल देगा। पैकेजिंग सिस्टम स्वचालित रूप से बैग बनाना, नाइट्रोजन भरना, सील करना और गिनती करना समाप्त कर देगा। तैयार उत्पादों को आउटपुट कन्वेयर द्वारा पहुंचाया जाएगा।

आलू चिप्स पैकेजिंग मशीन के मुख्य घटक

Top(Henan) Packing Machinery पर बिक्री के लिए मल्टी-हेड वीयर पोटैटो चिप्स पैकेजिंग मशीनें हैं। मशीन मुख्यतः शुल्क को एक वजन प्रणाली और एक पैकेजिंग प्रणाली पर केंद्रित है। वजन प्रणाली से उद्देश्य मल्टी-हेड वीयर है, और पैकेजिंग प्रणाली एक लैपेल पैकिंग मशीन है क्योंकि बैग बनाने वाले का आकार लैपेल के समान है। बहु-योग व्यवस्थापन कुशलता से और सटीकता के साथ काम करते हैं। अन्य मशीनों की तुलना में लैपेल पैकिंग मशीन डबल बेल्ट कन्वेइंग फिल्म प्रणाली को अपनाती है जो अधिक सामग्री को स्थिर रूप से सपोर्ट कर सकती है। मशीन के नीचे, एक ट्रे बैफर के तौर पर इस्तेमाल किया जाता है ताकि पैकेजिंग बैग की सुरक्षा हो सके।

आलू चिप्स पैकेजिंग मशीन की कीमत क्या है?

The multi-head scale potato chips packing machine की कीमत मुख्य रूप से इसके निर्माण सामग्री, उपयोग की गई तकनीक, सहायक मशीनें, और फ्रेट से संबंधित है। मल्टी-हेड वीयर पैकेजिंग उपकरण खाद-ग्रेड स्टेनलेस स्टील से बना है जिसमें अच्छी.properties हैं। पूरा पैकिंग प्रोцесс पूरी तरह से ऑटोमेटिक है जिसमें मानव हस्तक्षेप कम है। बहु-योग संयोजन वेयर कुशलतापूर्वक और सटीक रूप से काम करते हैं, मध्यम और बड़े पोटैटो चिप्स उत्पादन आउटपुट के लिए उपयुक्त। पैकेज सिस्टम न्यूमैटिक बल द्वारा संचालित है, स्थिर गति से चलता है, दीर्घ सेवा समय, और एयर कंप्रेसर के साथ संयोजन की आवश्यकता होती है। इसके अलावा, यह आम तौर पर Z-टाइप कन्वेयर के साथ काम करता है क्योंकि मशीन इतनी ऊँची होती है कि सामग्री को मैन्युअली लोड करना मुश्किल होता है। विभिन्न परिवहन तरीकों के लिए फ्रेट अलग-अलग होता है। यदि आप विशिष्ट कोटेशन पाना चाहते हैं, तो कृपया हमसे संपर्क करें contact us और हम जल्द से जल्द आपका उत्तर देंगे।

मल्टी-हेड स्केल आलू चिप्स पैकिंग मशीन क्यों चुनें?

- यह मध्यम और बड़े पैमाने पर उत्पादन उत्पादन को थोड़ा मानवीय हस्तक्षेप के साथ पूरा कर सकता है।

- पैकेजिंग प्रणाली वायवीय ड्राइविंग, अच्छे प्रदर्शन, लंबी सेवा जीवन को अपनाती है।

- पूरी तरह से स्वचालित पैकिंग प्रक्रिया, श्रम और समय की बचत।

- खाद्य-ग्रेड स्टेनलेस स्टील को अपनाएं, टिकाऊ, रखरखाव और साफ करने में सुविधाजनक।

- पैकेजिंग का वजन प्रति बैग 3 किलोग्राम तक हो सकता है।

- सर्वो फिल्म बेल्ट कन्वेयर डबल फिल्म खींचने वाले पहियों की तुलना में अधिक सामग्री वाले बड़े पैकेजिंग बैग का समर्थन कर सकता है।

- 10 हेड वेगर और 14 हेड वेगर वैकल्पिक हैं, और हेड की संख्या को आपकी वास्तविक आवश्यकताओं के अनुसार अनुकूलित किया जा सकता है।

- हम आपकी विशिष्ट आवश्यकताओं के आधार पर OEM सेवा का समर्थन करते हैं।

[contact-form-7 id=”17″ title=”Contact”]