3 मिनट में मल्टीहेड वेइगर पैकिंग मशीन के बारे में सच्चाई

मल्टी-हेड वेटर पैकिंग मशीन (जिसे कॉम्बिनेशन स्केल पैकिंग मशीन भी कहा जाता है), का व्यापक रूप से सभी क्षेत्रों में उपयोग किया जाता है। इस मशीन से, आप अपने प्रोजेक्ट की उत्पादकता में काफी सुधार कर सकते हैं। इसके अलावा, यह आपको बहुत कम समय में लाभ कमाने और आपके उत्पादों के लिए प्रतिस्पर्धा बनाए रखने में मदद कर सकती है। आम तौर पर, 10 हेड मल्टीहेड वेटर मशीन और 14 हेड मल्टीहेड वेटर का आमतौर पर इस्तेमाल किया जाता है। वास्तव में, मल्टीहेड वेटर मशीन बड़े और मध्यम उत्पादन आवश्यकताओं के लिए उपयुक्त है। और शायद छोटे कारखानों के लिए थोड़ी महंगी है। इसलिए, आपके व्यवसाय के लिए उपयुक्त पैकिंग मशीन चुनना महत्वपूर्ण है। इस लेख को पढ़ने के बाद, आपके पास मल्टीहेड वेटर पैकिंग मशीन का एक पूरा अवलोकन होगा।

मल्टीएड वेइगर पैकिंग मशीन क्या है?

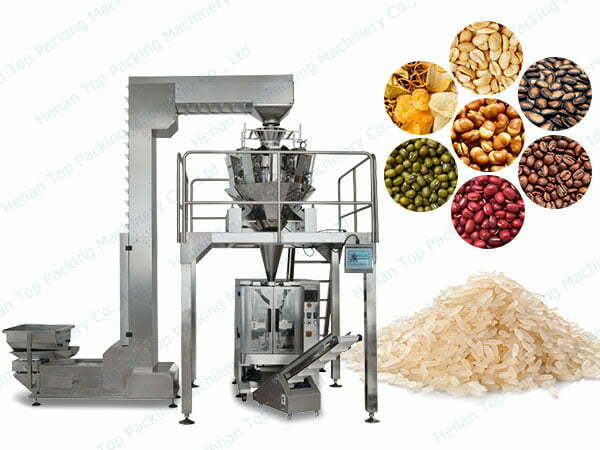

मल्टीहेड वेटर पैकिंग मशीन एक प्रकार की ऑटोमैटिक पैकिंग मशीन है। इसमें मुख्य रूप से मल्टीहेड वेटर, एलेवेटर, पैकिंग मशीन, मशीन प्लेटफॉर्म, उत्पाद कन्वेयर शामिल हैं। एक मल्टीहेड वेटर पैकिंग मशीन पूरी तरह से स्वचालित रूप से आइटम फीडिंग, वजन, फिलिंग, बैग बनाना, सीलिंग, कटिंग और कोडिंग की प्रक्रिया को पूरा कर सकती है। यह विभिन्न दानेदार उत्पादों, जैसे बीन्स, नट्स, अनाज, कैंडी, चाय, स्नैक्स, नमक, चीनी, ब्रेड, चॉकलेट, मछली, आदि की पैकेजिंग के लिए यहां एक सुपर-कुशल उपकरण है।

मल्टी हेड वेइगर पैकिंग मशीन कैसे काम करती है?

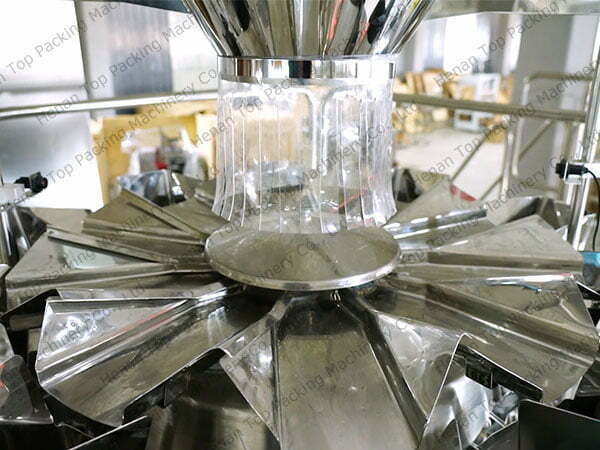

आम तौर पर, एक मल्टी-हेड वेगर पैकिंग मशीन थोक उत्पादों को लेती है और उन्हें अपने सॉफ़्टवेयर में प्रोग्राम किए गए वजन के आधार पर छोटे वेतन वृद्धि में तौलती है। थोक उत्पाद शीर्ष पर फ़ीड हॉपर के माध्यम से स्केल में प्रवेश करता है। शीर्ष शंकु और फ़ीड पैन कंपन करते हैं और धीरे से उत्पाद को स्केल के किनारे के आसपास वजन करने वाली बाल्टियों की ओर ले जाते हैं, जो लगातार अंदर मौजूद उत्पाद का वजन करते हैं। लक्ष्य वजन तक पहुंचने के लिए, सॉफ्टवेयर बैरल संयोजनों की सही संख्या का योग चुनता है। मानक मल्टीहेड स्केल 10 हेड से लेकर 24 हेड तक होते हैं। किसी सिस्टम में जितने अधिक वज़न वाले हेड होंगे, उतनी अधिक गति और सटीकता संभव होगी।

हेनान टॉप मल्टी हेड वेगर मशीन के अनूठे फायदे

बिक्री के लिए मल्टी हेड वेटर पैकिंग मशीन में अन्य ऑटोमैटिक पैकिंग मशीनों की तुलना में अनूठे फायदे हैं।

- यूजर फ्रेंडली। हमारी सभी मल्टीहेड वेइगर मशीनें पीएलसी प्रोग्राम सिस्टम और एक बड़ी टच स्क्रीन से सुसज्जित हैं। यह सुनिश्चित करने के लिए कि संवेदनशील पैरामीटर सेटिंग्स समायोजित नहीं की जाती हैं, ऑपरेटर सुरक्षा सुरक्षा विकल्पों की एक श्रृंखला उपलब्ध है। और तत्काल और स्पष्ट समस्या निवारण के लिए स्व-नैदानिक आरसीयू इंटरफ़ेस।

- साफ करने में आसान और स्वच्छ। हेनान शीर्ष कंपनी खाद्य जाल को खत्म करने और प्रमुख घटकों को अधिक सुलभ और साफ करने के लिए अधिक कुशल बनाने के लिए मानक तरीकों का उपयोग करने के लिए अपने विकास संसाधनों को अपने बढ़ते व्यावहारिक अनुभव के साथ जोड़ता है। प्रत्येक हॉपर को बस हाथ से उठाया जा सकता है और वॉशिंग दीवार पर या वॉशिंग मशीन में रखा जा सकता है।

- उत्कृष्ट वजन सटीकता। मल्टीहेड स्केल की गति और दक्षता के पीछे की उन्नत तकनीक भी अधिक सटीकता लाती है। यह सुनिश्चित करता है कि प्रत्येक वजन में लक्ष्य वजन के करीब पहुंचने, उपज को अधिकतम करने और एक ग्राम के अंश तक उपहार को कम करने की अधिक संभावना है।

मल्टी हेड कॉम्बिनेशन वेटर का व्यापक अनुप्रयोग

स्थिर प्रदर्शन और उच्च दक्षता के साथ, मल्टी हेड वेइगर पैकिंग मशीन को कई उद्योगों में लागू किया गया है, जैसे खाद्य और पेय उद्योग, फार्मास्युटिकल उद्योग, रसायन उद्योग, आदि। और खाद्य और पेय उद्योग 50% से अधिक राजस्व के साथ मल्टीहेड वेइगर मशीन बाजार में अग्रणी है। 2020 में हिस्सेदारी। बाजार की वृद्धि भोजन की मात्रा को सटीक रूप से मापने और अतिरिक्त उत्पाद उपहारों को कम करने के लिए उद्योग भर में मल्टीहेड स्केल को व्यापक रूप से अपनाने से प्रेरित है। इसके अलावा, पैकेज्ड फूड की बढ़ती वैश्विक मांग पूरे उद्योग में मल्टी-हेड स्केल की मांग को बढ़ा रही है। इसके अलावा, उपभोक्ता की बदलती प्राथमिकताएं और जीवनशैली भी बाजार के विकास को चलाने वाली प्रमुख ताकतें हैं।

ग्लोबल मल्टी हेड वेगर मार्केट विश्लेषण 2022

वैश्विक स्तर पर, मल्टीहेड वजन मशीन बाजार 2022 से 2029 तक पूर्वानुमानित अवधि के दौरान 3.3% की सीएजीआर से बढ़ने की उम्मीद है और 2029 तक 286.6 मिलियन अमेरिकी डॉलर तक पहुंचने की उम्मीद है। बाजार की वृद्धि सटीकता वजन की बढ़ती मांग से प्रेरित है और दक्षता. संगठन कई कार्यक्षेत्रों में उपयोग किए जाने वाले विभिन्न प्रकार के उत्पादों को स्वचालित रूप से और सटीक रूप से तौलने के लिए मल्टीहेड संयोजन स्केल का उपयोग कर रहे हैं। वज़न मापने वाले उपकरणों में तकनीकी प्रगति ने मल्टीहेड वेवर्स को अपनाने में और तेजी ला दी है। बाज़ार के खिलाड़ी उत्पाद की कार्यक्षमता और गुणवत्ता में सुधार के लिए लगातार काम कर रहे हैं। कंपनियां बिस्कुट और वेफर्स सहित खाद्य और पेय उद्योग में नाजुक और नाजुक उत्पादों के लिए वजन सटीकता और प्रतिक्रिया समय में सुधार करने के लिए काम कर रही हैं। इससे बाजार की वृद्धि में और तेजी आती है। इसके अलावा, समग्र उत्पाद उपहारों को कम करने के लिए विशिष्ट उत्पादन आउटपुट को पूरा करने के लिए मल्टी-हेड स्केल की बढ़ती मांग भी बाजार के विकास में योगदान दे रही है।