बैग फीडिंग मशीन और अन्य पैकिंग मशीनों पर अंतर

बैग फीडिंग मशीन में मुख्य रूप से एक सामग्री फीडिंग सिस्टम और एक बैग फीडिंग सिस्टम शामिल है। पैकेजिंग बैग पूर्वनिर्मित बैग को अपनाते हैं। लोग विभिन्न प्रकार के पूर्व-निर्मित बैग स्वतंत्र रूप से डिज़ाइन कर सकते हैं। अन्य पैकिंग मशीनें बैग को आकार देने के लिए बैग निर्माताओं से सुसज्जित हैं, इसलिए बैग फीडिंग उपकरण की तुलना में इसकी पैकेजिंग बैग शैली सीमित है। बैग फीडिंग मशीन स्वचालित रूप से बैग लेना, तारीख की छपाई (वैकल्पिक), बैग को भरने के लिए खोलना, बैग को पकड़ना, बैग के मुंह के आसपास की सामग्री को साफ करना (वैकल्पिक) और बैग को सील करना समाप्त कर सकती है। जबकि अन्य स्वचालित बैग पैकिंग मशीनें पैमाइश, बैग बनाना, कोडिंग (वैकल्पिक), भरना, सील करना और काटना पूरा कर सकती हैं।

विशेषताएँ

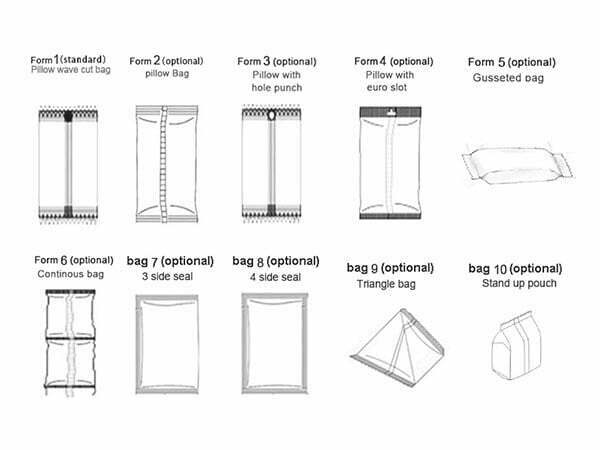

- अन्य पाउच पैकिंग मशीनें बैग निर्माता द्वारा बैग सील बैग, 3-साइड सील बैग, 4-साइड सील बैग और पिरामिड बैग बना सकती हैं। बैग फीडिंग मशीन न केवल उन बैगों पर लागू होती है, बल्कि स्टैंड-अप बैग और बैग के अनियमित आकार पर भी लागू होती है।

- पूर्वनिर्मित बैग का संवहन मार्ग क्षैतिज या रोटरी है। जबकि साधारण बैग पैकिंग उपकरण पैकेजिंग बैग को क्षैतिज या लंबवत रूप से घुमाते हैं।

- पूर्व-निर्मित बैग भरने और सील करने की मशीन वायवीय उपकरण को अपनाती है, जो स्थिर रूप से काम करती है। पैकेजिंग प्रक्रिया की जांच करने, बैग की बर्बादी से बचने, लागत बचाने के लिए कई डिटेक्टर।

- पाउच फीडिंग मशीन विभिन्न सामग्री फीडिंग सिस्टम के साथ मिलान करके विभिन्न सामग्रियों को पैकेज कर सकती है। और भरने के लिए पूर्वनिर्मित बैगों की कार्यशील स्थितियों की संख्या ग्राहक की आवश्यकताओं के आधार पर अनुकूलित की जाती है।

- क्षैतिज थैली फीडिंग मशीन और रोटरी बैग फीडिंग मशीन उपलब्ध हैं।

- अनुकूलन सेवा उपलब्ध है

अनुप्रयोग

बैग फीडिंग मशीन सभी प्रकार के पूर्व-निर्मित बैग, विशेष रूप से स्टैंड-अप बैग, विभिन्न सामग्री भरने और सील करने के लिए उपयुक्त है। विभिन्न भरने वाले उपकरणों से सुसज्जित होकर, यह पाउडर, दाना, तरल, पेस्ट, टुकड़े आदि को पैकेज कर सकता है। उदाहरण के लिए, मल्टी-हेड वेइगर से मेल खाने वाले दानों को पैक कर सकता है, जैसे स्नैक्स, बिस्कुट, कैंडी, पॉपकॉर्न, मूंगफली, तरबूज के बीज, आदि। तरल और पेस्ट के लिए, शुद्ध पानी, पेय पदार्थ, तेल, टमाटर सॉस, सलाद ड्रेसिंग, मिर्च सॉस, जैम, शैम्पू आदि भरने के लिए तरल और पेस्ट भरने वाले उपकरण हैं।

आम तौर पर, वैक्यूम पैकिंग मशीनों को छोड़कर अन्य बैग पैकिंग मशीनों को स्वयं बैग बनाने की आवश्यकता होती है। पैकिंग बैग की शैलियों में बैग सील, 3-साइड सील, 4-साइड सील, त्रिकोण बैग, गसेटेड बैग, पिलो बैग, आदि शामिल हैं। जैसा कि नाम से पता चलता है, ग्रेन्यूल पैकिंग मशीन विभिन्न ग्रेन्यूल्स पर लागू होती है, जैसे बीन्स, नट्स, बीज, मूंगफली, पॉपकॉर्न, अनाज, आदि। पाउडर पैकेजिंग मशीन का उपयोग मिल्क पाउडर, आटा, मक्के का आटा, मसाला पाउडर पैक करने के लिए किया जाता है। पिलो पैकिंग मशीन कुछ आकार की ठोस वस्तुओं, जैसे ब्रेड, बिस्कुट, डिब्बाबंद भोजन, इंस्टेंट नूडल्स, कपड़े, तौलिया, साबुन, शीशा, आदि के लिए उपयुक्त है। एक मल्टी-हेड कॉम्बिनेशन पैकिंग मशीन बैक सील बैग के लिए विभिन्न ग्रेन्यूल्स पर लागू होती है।

संरचनाएं

पूर्व-निर्मित बैग फीडिंग मशीन में कंट्रोल पैनल, मैकेनिकल आर्म, बैग के लिए काम करने की स्थिति, फिलिंग डिवाइस, वायवीय डिवाइस, सीलिंग डिवाइस, डेट प्रिंटर (वैकल्पिक), ब्रश (वैकल्पिक), आउटपुट ट्रे आदि शामिल हैं। पीएलसी रंग टच स्क्रीन का उपयोग बहुत सारे पैरामीटर सेट करने के लिए किया जाता है। आउटपुट ट्रे तैयार उत्पादों की सुरक्षा के लिए एक कुशन है। अन्य बैग पैकिंग मशीनें (वैक्यूम पैकिंग मशीनों को छोड़कर) एक कंट्रोल पैनल, हॉपर, बैग मेकर, फिल्म रोल होल्डर, वर्टिकल सीलिंग, हॉरिजॉन्टल सीलिंग, कटर आदि से बनी होती हैं। ये सभी सुरक्षा एहतियात के तौर पर एक आपातकालीन बटन से लैस हैं।

निष्कर्ष

बैग फीडिंग मशीनें और अन्य पैकिंग मशीनें मुख्य रूप से अपनी विशेषताओं, अनुप्रयोगों, संरचनाओं आदि में भिन्न होती हैं। पैकिंग मशीनों का चयन करते समय, अपनी वास्तविक आवश्यकताओं और बजट के अनुसार सबसे उपयुक्त चुनना बेहतर होता है। यदि आप अपनी विशिष्ट आवश्यकताओं के आधार पर मशीन को अनुकूलित करना चाहते हैं, तो आप अधिक विवरण प्राप्त करने के लिए हमसे संपर्क कर सकते हैं और हम आपको जल्द से जल्द जवाब देंगे।

[contact-form-7 id=”17″ title=”Contact”]