افقی پاؤچ فیڈنگ مشین

| ماڈل | D-150 |

| طاقت | 380V/50-60HZ (3 فیز) |

| پیکیجنگ کی رفتار | 25-45 بیگ/منٹ |

| پیکیجنگ کا سائز | W60-160mm، L100-250mm |

| پیکیجنگ کی صلاحیت | 800 ملی لیٹر |

| مشین کا سائز | L1700*W1050*H1100mm |

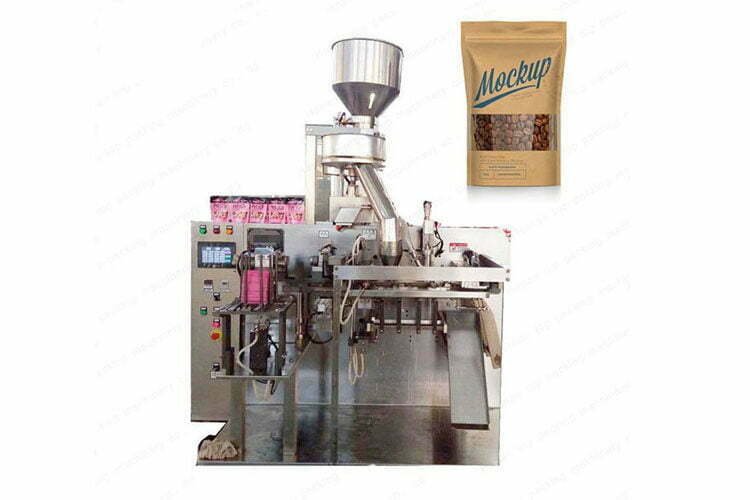

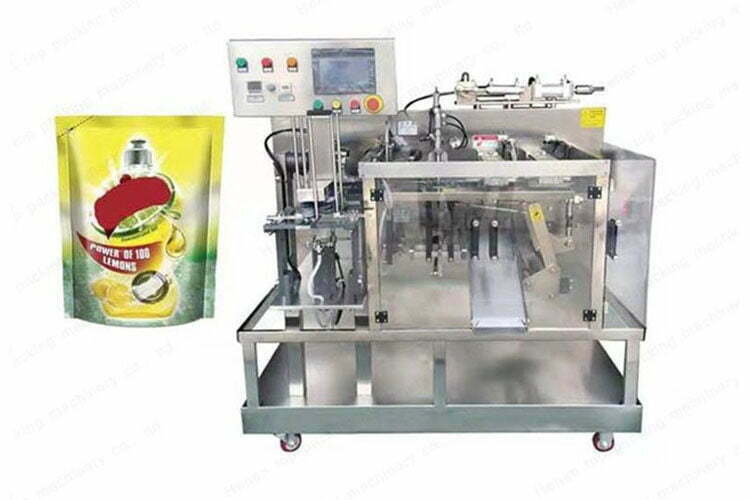

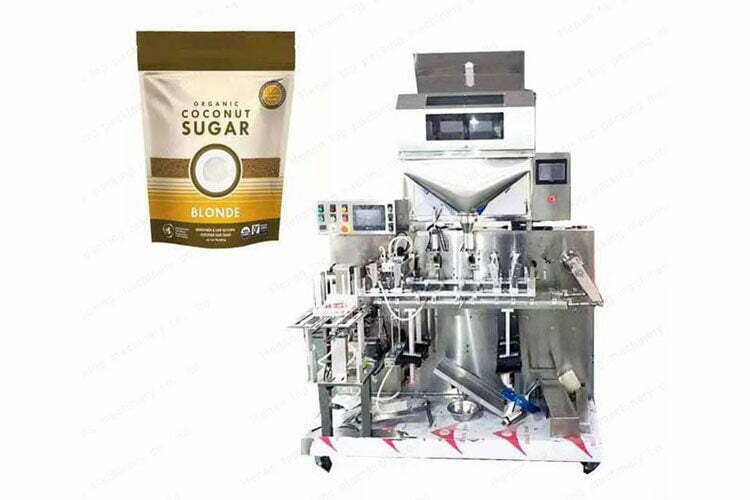

ہوری زونٹل پاؤچ فیڈنگ مشین ایک قسم کی پری-میڈ بیگ پیکنگ مشین ہے، جو بنیادی طور پر ایک مواد فیڈنگ سسٹم اور ایک بیگ فیڈنگ سسٹم پر مشتمل ہے۔ یہ سامان مختلف حالتوں کے مواد، پاؤڈر، دانے، مائع، پیسٹ وغیرہ کو مختلف فیڈنگ سسٹمز کو تبدیل کرکے پیک کر سکتا ہے۔ پیکنگ بیگ کو مشین شروع کرنے سے پہلے تیار کرنا اور ایک مخصوص جگہ پر رکھنا ضروری ہے۔ یہ مختلف اقسام کے بیگ کے لیے موزوں ہے، جیسے کہ اسٹینڈ-اپ پاؤچز، زپ بیگ، تین طرف سیل بیگ، چار طرف سیل بیگ، کاغذ کے بیگ، وغیرہ۔ پیکنگ کی رفتار بھرنے کی رفتار اور پیکنگ بیگ کی صلاحیت سے قریبی تعلق رکھتی ہے۔ مزید یہ کہ، ہم گھومنے والی بیگ فیڈنگ مشینیں بھی فراہم کرتے ہیں۔ مشینوں کے تمام سائز آپ کی ضروریات کے مطابق حسب ضرورت بنائے جا سکتے ہیں۔

افقی پاؤچ فیڈنگ مشین برائے فروخت

پہلے سے تیار پاؤچ بھرنے اور سگ ماہی کرنے والی مشینوں کو مختلف فیڈنگ ڈیوائسز سے لیس کیا جاسکتا ہے تاکہ مواد کی مختلف حیثیت کو پُر کیا جاسکے۔ مثال کے طور پر، اگر آپ پاؤڈر کو پیک کرنا چاہتے ہیں، تو کھانا کھلانے کا حصہ فلنگ کے حجم کو کنٹرول کرنے کے لیے سرپل اوجر کے ساتھ ایک ہاپر ہے۔ اسی طرح، ماپنے والے کپ کے ساتھ ٹرن ٹیبل چھوٹے دانے داروں کی پیکنگ کے لیے، بڑے دانے کے لیے ملٹی ہیڈ ویجر، مائعات کے لیے مائع پائپ، پیسٹ کے لیے پیسٹ بیرل کے لیے استعمال کیا جاتا ہے۔ افقی پاؤچ فیڈنگ مشین افقی پاؤچ فیڈنگ سسٹم کو اپناتی ہے، بھرنے اور سیل کرنے کے لیے کئی کام کرنے والی پوزیشنوں سے گزرتی ہے۔ اس کے علاوہ، ہم روٹری پاؤچ فیڈنگ مشین بھی فراہم کرتے ہیں۔ اس کے علاوہ، OEM سروس آپ کی ضروریات کے مطابق دستیاب ہے. مزید تفصیلات حاصل کرنے کے لیے ہم سے رابطہ کریں، اور ہم آپ کو جلد از جلد جواب دیں گے۔

افقی پاؤچ فیڈنگ مشین کے پیرامیٹرز

| قسم | TH-200 | D-150 | D-200 | D-250 |

| طاقت | 380V/2.5KW | 380V/50-60HZ (3 فیز) | 380V/50-60HZ (3 فیز) | 380V/50-60HZ (3 فیز) |

| پیکیجنگ کی رفتار | 20-50 بیگ/منٹ | 25-45 بیگ/منٹ | 25-45 بیگ/منٹ | 25-45 بیگ/منٹ |

| پیکیجنگ کا سائز | 100-210 ملی میٹر/110-320 ملی میٹر | W60-160mm، L100-250mm | W80-210mm، L100-320mm | W100-260mm، L110-350mm |

| پیکیجنگ کی صلاحیت | 20-1000 گرام (فلنگ مواد پر منحصر ہے) | 800 ملی لیٹر | 1200 ملی لیٹر | 2000 ملی لیٹر |

| ہوا کی کھپت | 0.7m3/منٹ | 0.3m3/منٹ | 0.3m3/منٹ | 0.3m3/منٹ |

| مشین کا وزن | 600 کلوگرام | / | / | / |

| مشین کا سائز | / | L1700*W1050*H1100mm | L2150*W1350*H1300mm | L2450*W1200*H1200mm |

افقی پری میڈ پاؤچ بھرنے والی مشین کی خصوصیات

- مناسب ڈیزائن، خودکار پیکیجنگ، سادہ آپریشن، وسیع ایپلی کیشنز

- مشین کے لیے پیکیجنگ سائز کے دائرہ کار میں مختلف قسم کے پہلے سے بنے ہوئے بیگ کے لیے موزوں ہے۔

- مواد کی حیثیت کے مطابق کھانا کھلانے کے مختلف آلات سے لیس، جیسے پاؤڈر، گرینول، مائع یا پیسٹ وغیرہ۔

- ملٹی فنکشنل ڈیزائن، ملٹی لینگویج سپورٹ کے ساتھ PLC کلر ٹچ اسکرین، پیکیجنگ پیرامیٹرز کو آسانی سے ترتیب دینا

- امپورٹڈ ڈیٹیکٹر کو اپنائیں، کوئی فلنگ میٹریل نہیں سیلنگ، پیکیجنگ بیگ کو محفوظ کریں، کام کرنے کے عمل کو آسانی سے جاری رکھنے کو یقینی بنائیں

- پریفارمڈ بیگ رکھنے کی پوزیشن آسان ہے، خودکار پریسنگ بیگ ڈیوائس سے لیس ہے۔

- مہر پر لمبی گھسیٹنے والی پلیٹ پیک شدہ اشیاء کو ایک خاص حد تک بفر کرنے میں کردار ادا کرتی ہے۔

- افقی پاؤچ فیڈنگ مشین فوڈ پروسیسنگ مشینری کے سینیٹری معیارات پر پورا اترتی ہے، اور اس کے مواد کے ساتھ رابطے میں 304 سٹینلیس سٹیل یا دیگر مواد ہیں جو کھانے کی حفظان صحت اور حفاظت کو یقینی بنانے کے لیے کھانے کی حفظان صحت کی ضروریات کو پورا کرتے ہیں۔

- حسب ضرورت سروس دستیاب ہے۔

پہلے سے تیار پاؤچ بھرنے اور سگ ماہی کرنے والی مشین کی وسیع ایپلی کیشنز

افقی پاؤچ فیڈنگ مشین میں کھانے، مسالا، کیمیائی مصنوعات، صابن، چٹنی، نمکین، کاسمیٹکس، مشروبات، روزمرہ کی ضروریات وغیرہ میں وسیع اطلاق ہوتا ہے۔

- پاؤڈر: دودھ پاؤڈر، کافی پاؤڈر، نیوٹریشن پاؤڈر، مصالحہ جات، کوکو پاؤڈر، کری پاؤڈر، ونیلا پاؤڈر، گڑ پاؤڈر، مسالاجات پاؤڈر، مرچ پاؤڈررنگ، ڈٹرجنٹ پاؤڈر، آٹا، کارن فلور، کیمیکل پاؤڈر، وغیرہ۔

- دانے دار: کینڈیمونگ پھلی، سبز پھلیاں، اناج کا مکس، چائے, چپس، خربوزے کے بیج، مونوسوڈیم گلوٹامیٹ، نمک، مکئی کے دانے، پستہ، پفڈ فوڈ، اناج، پاپ کارن وغیرہ۔

- مائع: دودھ، جوس، مشروب، چٹنی، پانیکھانے کا تیل، مونگ پھلی کا تیل، سوڈا، چاول کا سرکہ، ڈٹرجنٹ مائع، کاسمیٹکس، جراثیم کش ادویات، وغیرہ۔

- چسپاں کریں۔: ٹماٹر کی چٹنی، سلاد ڈریسنگ، مونگ پھلی کا مکھن، شہد، جام، شیمپو، کاسمیٹکس، ہینڈ سینیٹائزر وغیرہ۔

افقی تیلی کھانا کھلانے والی مشین کا ڈھانچہ

A horizontal pre-made bag packing machine بنیادی طور پر مادی_feeding device اور bag feeding device پر مشتمل ہوتی ہے۔ مادی_feeding سسٹم میں پاؤڈر بھرائی، granule بھرائی، مائع بھرائی, paste بھرائی وغیرہ کے آلات شامل ہوتے ہیں۔ بیگ فیڈنگ سسٹم میں بیگ لینا، تاریخ پرنٹنگ (اختیاری)، بیگ کو کھول کر بھرنا، بیگ کو رکھنا، بیگ کے منہ کے آس پاس مادی صاف کرنا (اختیاری)، بیگ پر بند کرنا، وغیرہ کے افعال ہوتے ہیں۔ اگر مادی بھرنا آسان نہیں ہے تو بیگ میں مادی بھرنے میں مدد کے لیے کمٰ فرش/وائبریشن ڈیوائس شامل کرنا بہتر ہے۔ زِیپر بیگ کو اضافی زِیپر کھولنے کا آلہ درکار ہوتا ہے۔ علاوہ ازیں، مشین کو کام کرتے ہوئے ہوا compressor کے ساتھ ملا کر چلانا ضروری ہے۔ بیگ کی چوڑائی 20 سینٹی میٹر سے کم ہونی چاہیے۔ اس کے علاوہ کچھ آلات اختیاری ہیں، ribbon printer، ink-jet printer، بیگ منہ کی صفائی کے لیے برش، puncher, zipper opening device، وغیرہ۔ Get in touch with us to get more information.

آلات پر فوٹو الیکٹرک آئی ڈٹیکٹر کے افعال

- معلوم کریں کہ آیا مکینیکل بازو بیگ لے جاتا ہے یا نہیں۔ اگر نہیں، تو مواد کو کھانا کھلانے والی مشین مواد کو نہیں بھرے گی، اور بیگ کو براہ راست پہنچا دیا جائے گا۔

- چیک کریں کہ بیگ کھلا ہے یا نہیں۔ اگر بیگ کھلا نہیں ہے، تب بھی یہ بیگ کو براہ راست باہر لے جائے گا۔

- کھانا کھلانے کے نظام کو چیک کریں، اگر بیگ میں مواد نہیں بھرتا ہے، تو سگ ماہی کا مرحلہ نہیں چلے گا۔

- پلاسٹک بیگ اعلی درجہ حرارت میں پگھلنا آسان ہے۔ اگر پلاسٹک ہیٹ کاپر بلاک سے چپک جاتا ہے، تو یہ خود بخود خطرے کی گھنٹی بجا دے گا تاکہ پروسیسنگ کو مستحکم طور پر یقینی بنایا جا سکے اور بیگ کے ضیاع سے بچا جا سکے۔

الیکٹرک اجزاء برانڈ کی فہرست

| آئٹم | برانڈ نام | پیداوار کی جگہ |

| پی ایل سی | سیمنز | جاپان |

| ٹچ اسکرین | وین ویو | تائیوان |

| درجہ حرارت کنٹرولر | اومرون | جاپان |

| سیلنگ ایئر سلنڈر | ایرٹیک | تائیوان |

| ویکیوم سولینائڈ والو | ایرٹیک | تائیوان |

| ویکیوم پریشر میٹر | ایس ایم سی | جاپان |

| پاور سوئچ | منگ وی | چین |