पाउडर पैकिंग मशीन क्या है?

पाउडर पैकिंग मशीन विभिन्न आधुनिक उद्योगों में अत्यधिक महत्वपूर्ण भूमिका निभाती है। इसे पाउडर उत्पादों को बैग, जार, डिब्बे या अन्य कंटेनरों में कुशलतापूर्वक और सटीक रूप से पैक करने के लिए डिज़ाइन किया गया है। पारंपरिक मैनुअल पाउडर उत्पादों की पैकेजिंग की तुलना में, स्वचालित पाउडर पैकेजिंग मशीन आपकी दक्षता में काफी सुधार कर सकती है और आपके व्यवसाय को लाभ पहुंचा सकती है। इस लेख में, हम पाउडर पैकिंग मशीनों के प्रकार, संरचना, कार्य सिद्धांत, फायदे, अनुप्रयोग, लागत और रखरखाव का पता लगाएंगे।

बिक्री के लिए पाउडर पैकिंग मशीन के प्रकार

विभिन्न पैकेजिंग आवश्यकताओं के लिए, मुख्य रूप से तीन अलग-अलग प्रकार की पाउडर पैकिंग मशीनें हैं:

छोटी वर्टिकल प्रकार की पाउडर फिल सील मशीन: छोटी वर्टिकल प्रकार की पाउडर फिल सील मशीन या छोटी पाउडर VFFS मशीन। इसकी पैकिंग क्षमता 0g से 100g तक है। इसमें छोटे आकार और किफायती कीमत की विशेषताएँ हैं, और यह छोटे व्यवसाय के लिए काफी उपयुक्त है।

पूर्ण स्वचालित पाउडर पैकिंग मशीन: पूर्ण स्वचालित पाउडर पैकिंग मशीन की विशेषताएँ सुपर दक्षता, बड़ी क्षमता और कॉम्पैक्ट संरचना हैं। इसकी पैकिंग रेंज 1kg से 3kg तक है। यह मध्यम उत्पादन आवश्यकताओं के लिए आदर्श है।

अर्ध स्वचालित पाउडर भरने वाली सीलिंग मशीन: अर्ध स्वचालित पाउडर भरने वाली सीलिंग मशीन 1kg से 10kg तक के सूखे पाउडर उत्पादों की पैकिंग कर सकती है। इसे एक स्क्रू कन्वेयर से सुसज्जित किया जा सकता है ताकि एक स्वचालित पाउडर पैकिंग लाइन बनाई जा सके। यह बड़ी पैकिंग आवश्यकताओं के लिए उपयुक्त है।

पाउडर पैकेजिंग मशीन की संरचनाएँ

पाउडर पैकिंग मशीन के मुख्य घटकों में हॉपर, वजन प्रणाली, भरने की प्रणाली, सीलिंग प्रणाली और नियंत्रण कक्ष शामिल हैं। हॉपर वह जगह है जहां पाउडर उत्पाद को तौलने और पैक करने से पहले संग्रहीत किया जाता है। वजन प्रणाली पैक किए जाने वाले उत्पाद की मात्रा को सटीक रूप से मापती है, जिससे यह सुनिश्चित होता है कि प्रत्येक बैग या कंटेनर उत्पाद की सही मात्रा से भरा हुआ है। पाउडर उत्पाद के साथ बैग या कंटेनर भरने के लिए फिलिंग सिस्टम जिम्मेदार है। परिवहन या भंडारण के दौरान उत्पाद को बाहर फैलने से रोकने के लिए सीलिंग प्रणाली बैग या कंटेनरों को सील कर देती है।

अंत में, कंट्रोल पैनल ऑपरेटर को मशीन की सेटिंग्स को सेट और एडजस्ट करने की अनुमति देता है, जैसे कि पैक किए जाने वाले उत्पाद की मात्रा, मशीन की गति और बैग या कंटेनर का आकार।

पाउडर पैकिंग मशीन का कार्य सिद्धांत

पाउडर पैकिंग मशीन के कार्य सिद्धांत में चार मुख्य चरण शामिल हैं: खिलाना और तौलना, भरना, सील करना, काटना और परिष्करण। फीडिंग और वजन चरण में, उत्पाद को हॉपर में डाला जाता है, और वजन प्रणाली उस उत्पाद की मात्रा को मापती है जिसे पैक करने की आवश्यकता होती है। भरने के चरण में, उत्पाद को हॉपर से निकाला जाता है और बैग या कंटेनर में पैक किया जाता है। सीलिंग चरण में, उत्पाद को बाहर फैलने से रोकने के लिए बैग या कंटेनर को सील कर दिया जाता है। अंत में, काटने और परिष्करण चरण में, बैग या कंटेनर को वांछित आकार और आकार में काटा जाता है, और किसी भी अतिरिक्त सामग्री को हटा दिया जाता है।

हमें पाउडर पैकेजिंग मशीन की आवश्यकता क्यों है?

पाउडर पैकिंग मशीन का उपयोग करने के कई फायदे हैं। सबसे पहले, पाउडर पैकिंग मशीनें अत्यधिक कुशल होती हैं, जिससे बड़ी मात्रा में उत्पाद जल्दी और सही तरीके से पैक किया जा सकता है। इससे श्रम लागत कम होती है और उत्पादकता बढ़ती है। दूसरे, पाउडर पैकिंग मशीनें उत्पादों को लगातार पैक करने में सक्षम हैं, जिससे यह सुनिश्चित होता है कि प्रत्येक बैग या कंटेनर में समान मात्रा में उत्पाद होता है, जिससे उत्पाद की गुणवत्ता में सुधार होता है। तीसरा, पाउडर पैकिंग मशीनें बहुमुखी और लचीली हैं, जो विभिन्न प्रकार के विभिन्न उत्पादों को विभिन्न आकार के बैग या कंटेनर में पैक करने में सक्षम हैं। यह उन्हें उद्योगों की एक विस्तृत श्रृंखला में उपयोग के लिए आदर्श बनाता है।

पाउडर पैकिंग मशीन के अनुप्रयोग

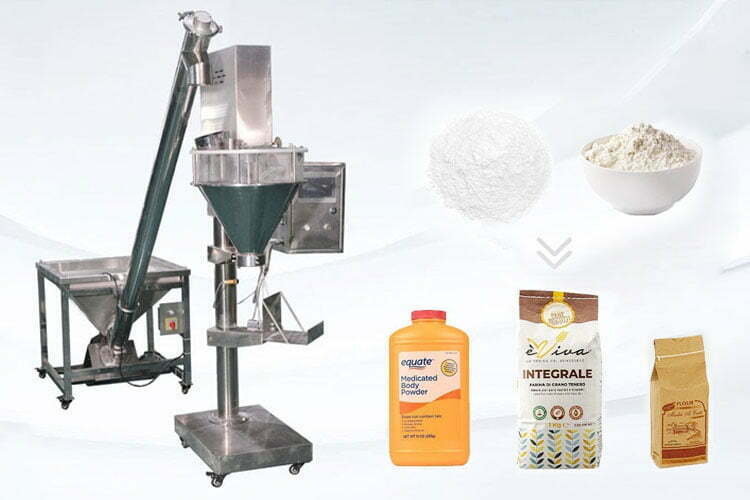

पाउडर पैकेजिंग मशीन विभिन्न सूखे पाउडर उत्पादों की पैकेजिंग के लिए डिज़ाइन की गई है।

उदाहरण:

आटा, कॉफी पाउडर, मसाला पाउडर, कपड़े धोने का पाउडर, जड़ी बूटी पाउडर, दूध पाउडर, प्रोटीन पाउडर, सीमेंट पाउडर, रासायनिक पाउडर, चिपकने वाला पाउडर, आदि।

पाउडर पैकेजिंग मशीन की कीमत क्या है?

पाउडर पैकिंग मशीन की कीमत कई कारकों से निकटता से संबंधित है, जैसे मशीन के प्रकार, मॉडल, कॉन्फ़िगरेशन, मशीन सामग्री, आदि और यहां तक कि परिवहन लागत भी। इसलिए अपनी पैकेजिंग आवश्यकताओं और बजट को स्पष्ट करना महत्वपूर्ण है, और हम आपकी परियोजनाओं के लिए सबसे उपयुक्त पाउडर पैकिंग मशीन का सुझाव दे सकते हैं। हमारी पैकिंग मशीनें अपनी उच्च गुणवत्ता और अच्छी कीमत के लिए प्रसिद्ध हैं। यदि आप अपना पाउडर पैकेजिंग व्यवसाय शुरू करना चाहते हैं, तो पाउडर पैकेजिंग मशीन की सर्वोत्तम कीमत के लिए आज ही हमसे संपर्क करें।

पाउडर पैकिंग मशीन का रखरखाव और समस्या निवारण

पाउडर पैकिंग मशीन के सुचारू संचालन को सुनिश्चित करने के लिए नियमित रखरखाव करना महत्वपूर्ण है। इसमें मशीन की सफाई और चिकनाई करना, किसी भी क्षतिग्रस्त हिस्से का निरीक्षण और मरम्मत करना और यह सुनिश्चित करना शामिल है कि मशीन ठीक से कैलिब्रेट की गई है। पाउडर पैकिंग मशीनों के साथ उत्पन्न होने वाली सामान्य समस्याओं में जाम, मिंग, गलत वजन और सीलिंग प्रणाली के मुद्दे शामिल हैं। किसी समस्या की स्थिति में, समस्या के कारण की पहचान करने और उचित समाधान निर्धारित करने के लिए मशीन का निवारण करना महत्वपूर्ण है।

निष्कर्ष

निष्कर्ष में, पाउडर पैकिंग मशीनें कई उद्योगों में उपकरण का एक अनिवार्य हिस्सा हैं जो पाउडर उत्पादों से निपटते हैं। वे बढ़ी हुई दक्षता, कम श्रम लागत, बेहतर उत्पाद गुणवत्ता और बहुमुखी प्रतिभा सहित कई लाभ प्रदान करते हैं। पाउडर पैकिंग मशीनें तीन मुख्य प्रकार की होती हैं, प्रत्येक के अपने फायदे और अनुप्रयोग होते हैं। मशीन के सुचारू संचालन को सुनिश्चित करने के लिए नियमित रखरखाव और समस्या निवारण करना महत्वपूर्ण है। जैसे-जैसे प्रौद्योगिकी आगे बढ़ती है, हम पाउडर पैकिंग मशीन प्रौद्योगिकी में और अधिक विकास देखने की उम्मीद कर सकते हैं, जिससे उनकी दक्षता और क्षमताओं में और भी सुधार होगा।

उम्मीद है कि यह लेख आपको बहुत मदद कर सकता है। और यदि आप एक पाउडर पैकिंग मशीन में रुचि रखते हैं, तो मशीन के विवरण और मुफ्त मूल्य सूची के लिए हमारे विशेषज्ञ से संपर्क करें।