मल्टी-हेड वेइगर: एक अल्टीमेट गाइड

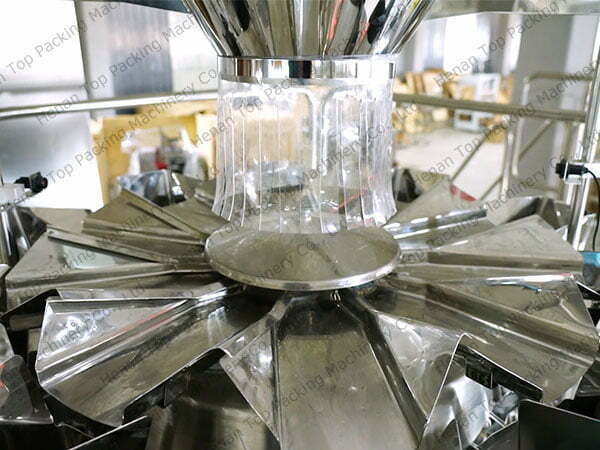

मल्टीहेड वेइगर का परिचय, सटीक वजन और कुशल पैकेजिंग का अंतिम समाधान। हमारा मल्टीहेड वेइगर एक उन्नत वजन मशीन है जिसे उत्पादन प्रक्रिया में गति, सटीकता और विश्वसनीयता बढ़ाने के लिए डिज़ाइन किया गया है। मशीन एक हॉपर, कई वेट हेड और एक डिस्चार्ज शूट से बनी है, सभी को इष्टतम प्रदर्शन के लिए सावधानीपूर्वक तैयार किया गया है।

हमारे मल्टीहेड वेइघर की कई हेडों में उत्पादों को सटीकता से वितरित करने की अनूठी क्षमता यह सुनिश्चित करती है कि प्रत्येक हेड की सटीकता बनी रहे, जिससे हमारे ग्राहकों को वजन प्रक्रिया में अद्वितीय सटीकता मिलती है। वेइघर प्रति मिनट 200 पैकेट तक वजन कर सकता है, जिससे उत्पादन का डाउनटाइम काफी कम हो जाता है और पैकेजिंग में दक्षता बढ़ जाती है। समय बचाने वाली यह सुविधा मशीन को उच्च गति वाली उत्पादन प्रक्रियाओं के लिए उपयुक्त बनाती है।

मल्टी-हेड वेगर क्या है?

4-हेड वजन पैकिंग मशीन बिक्री के लिए

मल्टी-हेड वेगर संरचना

एक मल्टीहेड वेइगर विभिन्न घटकों से बना होता है। इसमें फीडिंग सिस्टम है, जो वेटर का एक महत्वपूर्ण घटक है, जो यह सुनिश्चित करता है कि उत्पादों को हॉपर के पार सिर पर समान रूप से वितरित किया जाए। सिरों को उत्पादों का वजन करने के लिए डिज़ाइन किया गया है, और प्रत्येक सिर में स्प्रिंग-लोडेड वजन उठाने वाली बाल्टियाँ हैं। कंप्यूटर मस्तिष्क भी वजनकर्ता का एक अनिवार्य हिस्सा बनता है। यह प्रमुखों से डेटा एकत्र करता है और उत्पादों के अंतिम वजन की गणना करता है।

मल्टीहेड वेइगर मशीन का उपयोग करने के लाभ

मल्टीहेड वेइंग मशीन अद्वितीय सटीकता, गति और विश्वसनीयता प्रदान करती है। इन फायदों ने पैकेजिंग उद्योग में क्रांति ला दी है, और मल्टीहेड वेटर अब विनिर्माण संयंत्रों में सबसे व्यापक रूप से उपयोग किए जाने वाले वेटर हैं। मल्टीहेड वेइगर का उपयोग करने के कुछ फायदों में शामिल हैं:

उच्च सटीकता: मल्टीहेड वेटर अपनी उच्च स्तर की सटीकता के लिए जाने जाते हैं, जिसमें बहुत कम या कोई स्केल त्रुटि नहीं होती है। ये मशीनें सुनिश्चित करती हैं कि प्रत्येक पैकेट को आवश्यक सटीक वजन के साथ पैक किया गया है।

समय की बचत: मल्टीहेड वेइगर उत्पादों की तेज़ और सटीक पैकेजिंग की अनुमति देते हैं। ये मशीनें प्रति मिनट 200 पैक तक वजन कर सकती हैं, जो उन्हें उच्च गति के उत्पादन के लिए उपयुक्त बनाती हैं।

बहुमुखी: मल्टीहेड वेटर उत्पादों की एक विस्तृत श्रृंखला को संभाल सकते हैं और उपयोगकर्ता की विशिष्ट आवश्यकताओं को पूरा करने के लिए अनुकूलित किया जा सकता है।

उपयोग में आसान: मशीनें उपयोग में आसान इंटरफ़ेस के साथ आती हैं, जिससे उन्हें अनुभवहीन ऑपरेटरों के लिए भी उपयोग करना आसान हो जाता है।

मल्टीहेड वेइगर मशीन के अनुप्रयोग

मल्टीहेड वेगर खाद्य, फार्मा, रसायन और पालतू भोजन सहित विभिन्न उद्योगों पर लागू होता है। वे बहुमुखी हैं और कई प्रकार के उत्पाद संभाल सकते हैं, जिनमें चिप्स, स्नैक्स, कन्फेक्शनरी, नट्स और चिपचिपे या नाजुक उत्पाद जैसे ताजी कटी सब्जियां और फल शामिल हैं।

सही मल्टी-हेड वेइगर कैसे चुनें?

बिल्ट-इन

उत्पाद का प्रकार और विशेषताएँ

वजन सीमा और सटीकता

मशीन की गति

पर्यावरण

रखरखाव संबंधी आवश्यकताएँ

निष्कर्ष

मल्टीहेड वेइगर एक अत्याधुनिक वजन मशीन है जिसे उत्पादन प्रक्रिया में सटीकता, दक्षता और गति बढ़ाने के लिए डिज़ाइन किया गया है। यह बहुमुखी, अनुकूलन योग्य और संचालित करने में आसान है, जो इसे विभिन्न उद्योगों के लिए एक आदर्श समाधान बनाता है। इस मशीन को प्राप्त करने से आपकी उत्पादन प्रक्रिया में क्रांतिकारी बदलाव आएगा, जिससे गुणवत्तापूर्ण उत्पादन और लाभप्रदता में वृद्धि होगी।

धूप बत्ती पैकिंग मशीन का कार्य वीडियो