डबल चैम्बर वैक्यूम पैकेजिंग मशीन

| नाम | डबल चैम्बर वैक्यूम सीलर |

| ब्रांड | शुलि |

| सीलिंग स्ट्रिप्स की संख्या | 2*2पीसी |

| चैम्बर एवं आवरण सामग्री | 304 स्टेनलेस स्टील |

| अनुप्रयोग | मांस, सब्जी, फल, अनाज, समुद्री भोजन, आटा, अखरोट, आदि। |

| सेवा | अनुकूलन, बिक्री उपरांत सेवा और तकनीकी सहायता |

Shuliy डबल चेंबर वैक्यूम पैकेजिंग मशीन एक वैक्यूम सीलर है जिसमें दो वैक्यूम चैंबर होते हैं, जो मांस, सब्जी, फल, अनाज, समुद्री भोजन आदि की वैक्यूम पैकिंग के लिए उपयुक्त है। वैक्यूम पैकेजिंग प्रभावी ढंग से पैकिंग बैग में हवा को पंप करती है ताकि एरोबिक सूक्ष्मजीवों की संख्या को कम किया जा सके।

यह वैक्यूम सीलर मशीन बिना समय बर्बाद किए बारी-बारी से काम कर सकती है, सिंगल चैंबर वैक्यूम पैकिंग मशीन की तुलना में अधिक कुशल है। यह प्रति मिनट 3-10 पैकेज ख़त्म कर सकता है।

हमारी मशीन 304 स्टेनलेस स्टील से बनी है, और बिक्री के लिए 4 मॉडल हैं, जो ग्राहकों के लिए अधिक विकल्प प्रदान करते हैं। इसके अलावा, वैक्यूम पैकिंग मशीन को ओमान, मोकोरो, केन्या आदि में निर्यात किया गया है। यदि आप उपकरण में रुचि रखते हैं, तो किसी भी समय हमसे संपर्क करें!

शुली डबल चैम्बर वैक्यूम पैकिंग मशीन द्वारा वैक्यूम सील क्या किया जा सकता है?

डबल चैम्बर वैक्यूम पैकेजिंग मशीन निरंतर काम के साथ विभिन्न खाद्य सीलिंग के लिए उपयुक्त है। इस मशीन का खाद्य पैकेजिंग में व्यापक अनुप्रयोग है, जैसे:

- मांस: सॉसेज, बेकन, रोस्ट डक, सूखे टोफू, बीफ, मटन, पोर्क, चिकन, मछली, समुद्री भोजन, आदि।

- खाना: फल, सब्जियां, अनाज, बीन्स, मक्खन, मेवे, सूखे फल, बिस्कुट, मक्का, मूंगफली, आटा, आदि।

वैक्यूम पैकिंग के बाद, उत्पादों को ऑक्सीकरण, फफूंदी, कीड़ों और नमी से प्रभावी ढंग से रोका जा सकता है, भंडारण अवधि को बढ़ाया जा सकता है और उनका रंग बनाए रखा जा सकता है। वैक्यूम वातावरण एरोबिक सूक्ष्मजीवों के विकास और भोजन के खराब होने के लिए फायदेमंद नहीं है।

तीन प्रकार की वैक्यूम पैकिंग बैग सामग्री

वैक्यूम पैकिंग के परिणाम में वैक्यूम पैकेजिंग बैग सामग्री काफी महत्वपूर्ण कारक है। पैकेजिंग फिल्म के विभिन्न गुण अलग-अलग पैकिंग स्थितियों के अनुरूप होते हैं। वैक्यूम पैकिंग फिल्म सामग्री आमतौर पर कंपोजिट, गर्मी प्रतिरोधी सामग्री और एल्यूमीनियम पन्नी का उपयोग करती है।

- मुख्य कंपोजिट पीई, आरसीपीपी, एएल और दो, तीन या यहां तक कि चार सामग्रियों से बने होते हैं पालतू. पैकेजिंग फिल्मों के प्रदर्शन को बेहतर बनाने के लिए उन्हें कुछ तकनीकों के माध्यम से संयोजित किया जा सकता है।

- The गर्मी प्रतिरोधी फिल्म सामग्री उच्च तापमान का सामना कर सकता है, विभिन्न प्रकार के पके हुए भोजन के लिए उपयुक्त। इसकी संपत्ति कंपोजिट से बेहतर है, इसलिए इसकी कीमत अधिक है।

- The एल्यूमीनियम पन्नी नमी प्रतिरोधी, तेल प्रतिरोधी, सूरज की रोशनी को अवरुद्ध करने वाला, उच्च तापमान सहन करने वाला और सुगंध बनाए रखने वाला है।

आप उन उत्पादों के अनुसार फिल्म सामग्री का चयन कर सकते हैं जिन्हें आपको पैक करने की आवश्यकता है और आप किस पैकिंग परिणाम को प्राप्त करना चाहते हैं।

बिक्री के लिए डबल चैम्बर वैक्यूम पैकेजिंग मशीनों के मॉडल

फूडसेवियर वैक्यूम सीलर्स के एक पेशेवर निर्माता और आपूर्तिकर्ता के रूप में, बिक्री के लिए 4 प्रकार की डबल चैम्बर वैक्यूम पैकिंग मशीनें हैं। मॉडल का नाम इसकी सीलिंग स्ट्रिप की लंबाई पर निर्भर करता है।

| नमूना | एसएल-500 | एसएल-600 | एसएल-700 | एसएल-800 |

| वोल्टेज | 380V/50HZ(अनुकूलन योग्य 220V) | 380V/50HZ(अनुकूलन योग्य 220V) | 380V/50HZ | 380V/50HZ |

| वैक्यूम पंप शक्ति | 1.5 किलोवाट | 2.25 किलोवाट | 2.25 किलोवाट | 2.5 किलोवाट |

| सील करने की शक्ति | 1.17 किलोवाट | 1.17 किलोवाट | 1.17 किलोवाट | 1.17 किलोवाट |

| सबसे कम निरपेक्ष दबाव | 0.1pa | 0.1pa | 0.1pa | 0.1pa |

| सीलिंग स्ट्रिप्स की संख्या | 2*2पीसी | 2*2पीसी | 2*2पीसी | 2*2पीसी |

| सीलिंग स्ट्रिप्स का आकार | 500*10मिमी | 600*10मिमी | 700*10मिमी | 800*10मिमी |

| चैम्बर सामग्री | 304 स्टेनलेस स्टील | 304 स्टेनलेस स्टील | 304 स्टेनलेस स्टील | 304 स्टेनलेस स्टील |

| आवरण सामग्री | 304 स्टेनलेस स्टील | 304 स्टेनलेस स्टील | 304 स्टेनलेस स्टील | 304 स्टेनलेस स्टील |

| वैक्यूम पंप | 40m³/घंटा | 60m³/घंटा | 60m³/घंटा | 63m³/घंटा |

| चैंबर का आकार | 560*525*160मिमी | 660*530*160मिमी | 770*708*160मिमी | 880*708*160मिमी |

| मशीन का आकार | 1260*605*960मिमी | 1460*605*960 मिमी | 1645*730*960 मिमी | 1900*605*960मिमी |

| मशीन वजन | 150 किलो | 180 किलो | 260 किग्रा | 300 किलो |

इसका आवश्यक वोल्टेज 380V-50HZ है। हम आपकी आवश्यकताओं के अनुरूप वोल्टेज को भी अनुकूलित कर सकते हैं। वैक्यूम चैम्बर और कवर की सामग्री 304 स्टेनलेस स्टील को अपनाती है। प्रत्येक डबल-चेंबर वैक्यूम पैकेजिंग मशीन चार सीलिंग स्ट्रिप्स से सुसज्जित है। निचले दाएं कोने में संपर्क फ़ॉर्म भरकर अधिक जानकारी प्राप्त करें।

डबल चैम्बर वैक्यूम पैकेजिंग मशीन की विशेषताएं

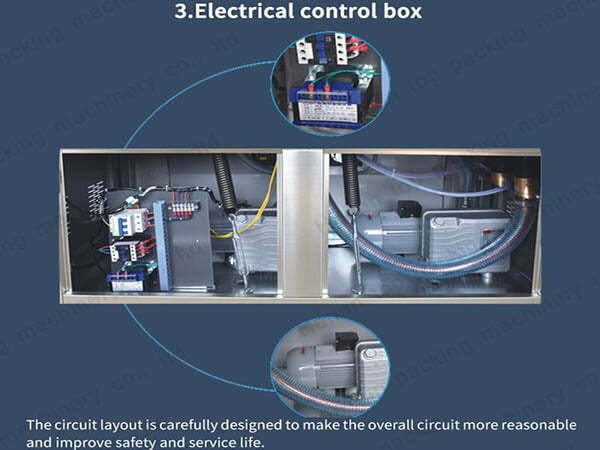

- इसमें एक है बुद्धिमान नियंत्रक, संचालित करने में सुविधाजनक।

- तुम कर सकते हो वैक्यूम, सीलिंग, कूलिंग और निकास का समय निर्धारित करें नियंत्रण कक्ष पर.

- तीन प्रकार के सीलिंग तापमान वैकल्पिक हैं, निम्न तापमान, मध्यम तापमान और उच्च तापमान।

- नियंत्रण कक्ष पर पूर्व-निर्धारित मापदंडों के अनुसार, वस्तुओं को वैक्यूम रूम में डालने और ढक्कन को बंद करने के बाद, मशीन वैक्यूम पैकेजिंग की प्रक्रिया स्वचालित रूप से पूरी हो जाती है.

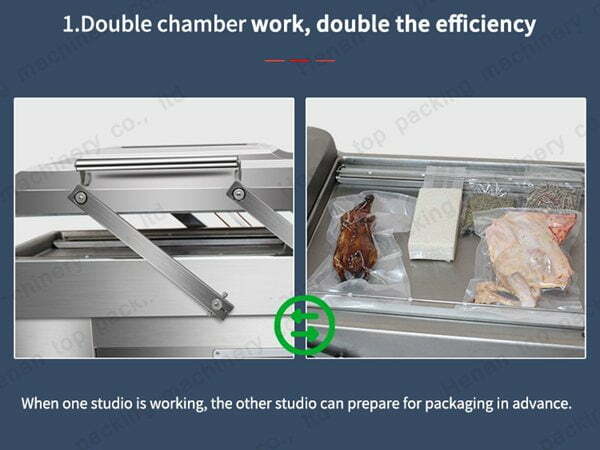

- दो निर्वात कक्ष बारी-बारी से उपयोग में आते हैं, अत्यधिक कुशल.

- डबल चैम्बर वैक्यूम पैकेजिंग मशीन है मध्यम और छोटी वस्तुओं की पैकिंग के लिए उपयुक्त.

- मशीन कर सकती है एक ही समय में एक ही वस्तु या कई वस्तुओं को पैक करें.

- अनुकूलन सेवा उपलब्ध है.

डबल चैम्बर वैक्यूम पैकेजिंग मशीन की संरचना

डबल चैंबर वैक्यूम सीलिंग मशीन एक कंट्रोल पैनल, एक मूवेबल कवर, दो वैक्यूम रूम, चार सीलिंग स्ट्रिप्स आदि से सुसज्जित है।

- नियंत्रण कक्ष वैक्यूम, सीलिंग, कूलिंग और निकास का समय निर्धारित कर सकता है।

- कवर को एक या दूसरे कक्ष में ले जाया जा सकता है। जब एक वैक्यूम रूम बंद हो जाता है, तो दूसरे को वैक्यूम पैकेजिंग के लिए तैयार किया जा सकता है, जिससे दक्षता में अत्यधिक सुधार होता है।

- प्रत्येक कक्ष में दो सीलिंग स्ट्रिप्स हैं। आप वैक्यूम चैम्बर के आकार के आधार पर पैकेजिंग बैग के खुले हिस्से को सीलिंग स्ट्रिप्स के नीचे रख सकते हैं।

डबल चैम्बर वैक्यूम पैकिंग मशीन की कीमत अलग-अलग क्यों है?

डबल चैम्बर वैक्यूम पैकेजिंग मशीन की कीमत वैक्यूम चैम्बर आकार, सीलिंग स्ट्रिप आकार और वैक्यूम पंप में भिन्न होती है, जो सीधे पैकेजिंग बैग आकार और कार्य कुशलता को प्रभावित करती है।

पैकिंग बैग का आकार वैक्यूम चैम्बर क्षमता और सीलिंग स्ट्रिप आकार पर निर्भर करता है। बड़े वैक्यूम रूम और सीलिंग स्ट्रिप का मतलब है कि उपकरण को अधिक सामग्री के उपयोग की आवश्यकता है।

डबल-चेंबर वैक्यूम सीलर मशीन की कार्य कुशलता वैक्यूम पंप से निकटता से संबंधित है। एक घंटे में वैक्यूम पंप की पंपिंग मात्रा जितनी अधिक होगी, पैकिंग की गति उतनी ही तेज होगी। इसके अलावा, हम पैकेजिंग मशीनों के बारे में आपकी वास्तविक आवश्यकताओं के आधार पर ओईएम सेवा का समर्थन करते हैं। सर्वोत्तम मूल्य के लिए यथाशीघ्र हमसे संपर्क करें।

हमें क्यों सहयोग करें – Shuliy Machinery?

- हमारी कंपनी की स्थापना 1992 में हुई थी, और हमने की है पेशेवर स्टाफ़ लगभग 30 वर्षों से पैकेजिंग मशीनों में लगे हुए हैं। हमारे पास डबल चैम्बर वैक्यूम पैकेजिंग मशीन निर्माण, आपूर्ति और वितरण की प्रक्रिया के बारे में परिपक्व प्रणालियों का एक सेट है।

- पर भरोसा उत्कृष्ट गुणवत्ता, प्रतिस्पर्धी मूल्य और विचारशील सेवा, हमने अमेरिका, कनाडा, ऑस्ट्रेलिया, इंग्लैंड, भारत, पाकिस्तान, मलेशिया, फिलीपींस, इंडोनेशिया, बांग्लादेश, केन्या, नाइजीरिया आदि जैसे 80 से अधिक देशों से ऑर्डर पूरे किए हैं।

- हमारे पास है एक अत्यंत सख्त निरीक्षण प्रणाली. शिपमेंट से पहले, हम मशीन का कड़ाई से निरीक्षण करेंगे और आपको तस्वीरें और वीडियो भेजेंगे। यदि उपकरण के बारे में आपके कोई प्रश्न हैं, तो 24 घंटे ऑनलाइन सेवा उपलब्ध है। और हम आपको यथाशीघ्र उत्तर देंगे.

- हम OEM सेवा का समर्थन करें. हम आपकी विशिष्ट आवश्यकताओं के अनुसार मशीनों का निर्माण कर सकते हैं। क्या आप इसमें रुचि रखते हैं? अधिक जानकारी प्राप्त करने के लिए हमसे संपर्क करें।

शुली से संबंधित पैकिंग मशीनें

पैकिंग मशीन निर्माता और आपूर्तिकर्ता के रूप में, हम डबल चैम्बर वैक्यूम पैकेजिंग मशीनों को छोड़कर अन्य प्रकार की पैकेजिंग मशीनें भी प्रदान करते हैं।

उदाहरण के लिए, सिंगल चेंबर वैक्यूम फूड सीलर, पाउडर पैकर मशीन, ग्रेन्यूल पैकेजिंग मशीन, लिक्विड पैकेजिंग मशीन, पिलो पैकिंग मशीन, आदि हैं।

यदि आप अच्छी गुणवत्ता और सर्वोत्तम कीमत वाली पैकेजिंग मशीन की तलाश में हैं, तो निःशुल्क कोटेशन प्राप्त करने के लिए आप आज ही हमसे संपर्क कर सकते हैं। हम आपके संदेश का इंतजार कर रहे हैं.