Çok başlı tartımlı paketleme makinesi

| Makine adı | Yaka dikey paketleme makinesi ile kombinasyon ölçeği |

| Paketleme hızı | 5-50 torba/dak |

| Ölçüm aralığı | 5-6000ml |

| Uygulamalar | Şişirilmiş gıda, tahıllar, kuru meyveler, sebzeler, fasulyeler, kuruyemişler, atıştırmalıklar, tohumlar, kahve, şekerleme vb. |

| İsteğe bağlı cihaz | Z tipi asansör, çalışma platformu, çıkış konveyörü, tarih yazıcı, azot dolum, zincir torba cihazı, delik açıcı vb. |

Shuliy çok başlı ağırlıklandırma makineli paketleme makinesi yüksek verimli ve hassas otomatik paketleme ekipmanıdır, tane, pul ve şerit malzemelerin nicelik olarak tartımını ve paketlemesini geniş ölçüde kullanılır. Ölçüm aralığı 5-6000ml ve paketleme hızı dakikada 5-50 çanta arasındadır.

Bu granül paketleme makinesi, çok başlı bir kombinasyon tartım cihazını (2 başlı, 4 başlı, 10 başlı, 14 başlı vb.) ve bir dikey yaka paketleme makinesini (SL-420, SL-520 ve SL-720) birleştirir. Ceviz, şekerlemeler, patlamış gıda, dondurulmuş gıda, tahıllar, çay, atıştırmalıklar gibi çeşitli ürünler için uygundur. Ağırlık doğruluğu ve paketleme hızı konusunda yüksek gereksinimleri olan üretim hatları için özellikle uygundur.

Ayrıca, gereksinimlerinize göre esnek ve özelleştirilmiş hizmetleri de destekliyoruz. Daha ayrıntılı bilgi ister misiniz? Bizimle iletişime geçin ve en kısa sürede size geri döneceğiz.

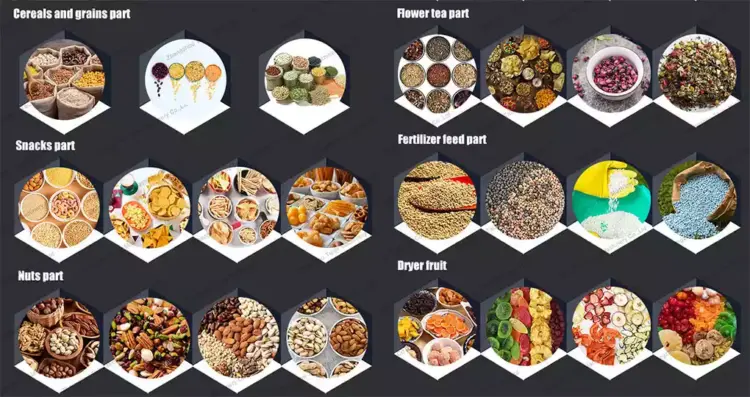

Otomatik çok başlı tartım makinesi paketleme makinesinin uygulamaları

Çok kafalı tartım paketleme makinemiz gıda, ilaç, endüstriyel parçalar ve diğer granül ürünlerin kantitatif paketlenmesinde yaygın olarak kullanılmaktadır. Farklı sektörlerin malzeme özelliklerine göre aşağıdaki gibi alt bölümlere ayrılabilir:

- şişirilmiş gıda

- Patates cipsi, pirinç krakeri, karides şeritleri, karides cipsi, soğan halkaları, kuru çiçekler vb.

- kuruyemiş ve kızartılmış gıda

- Fıstık, kavun çekirdeği, antep fıstığı, kestane, papaya, bakla, hurma, kuru üzüm ve diğerleri

- Hububat

- Pirinç, mısır, yulaf ezmesi, tahıllar, kahve çekirdekleri, bakla, yeşil fasulye, soya fasulyesi vb.

- Eğlence atıştırmalıkları

- Şekerleme, kurabiye, patlamış mısır, küçük hamur işleri, kuru meyve ve sebzeler, kuruyemiş ve atıştırmalıklar, bisküvi vb.

- İlaç ve endüstriyel granüller

- İlaç granülleri, sağlık gıda granülleri, donanım vidaları, plastik granüller, küçük endüstriyel parçalar vb.

- Diğerleri

- Buz tuğlaları, vb.

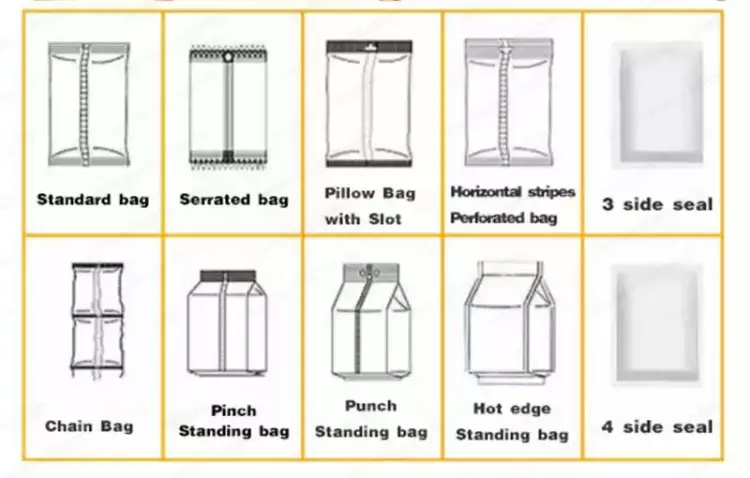

Yukarıda sadece bazı örnek malzemeler verilmiştir. Malzemenizin çok başlı tartım poşetleme makinesi ile paketlenip paketlenemeyeceğini öğrenmek istiyorsanız, lütfen doğrudan bizimle iletişime geçin. Paketleme şeklimiz aşağıda gösterildiği gibi çeşitli formlarda olabilir.

Çok başlı tartım ve doldurma makinesinin avantajları

- Bir 5-6000ml ölçüm aralığı, küçük, orta ve büyük poşet paketleme taleplerini karşılar.

- Bu makine otomatik olarak tartma, doldurma, torba oluşturma, mühürleme, kesme ve sayma işlemlerini tamamlar, yüksek otomasyon derecesine sahiptir.

- çok başlı tartım makinesi, kombinasyon terazilerini kullanır bir ±0.3-1.5g tartım hassasiyeti ile, verimli ve değerli.

- Bir programlanabilir kontrol sistemi ve büyük dokunmatik ekran, görsel ve anlaşılır.

- Yaka ambalaj makinesi, şunu benimser: servo film taşıma sistemi, film pozisyonuna duyarlı ve paketi düzenli ve düzgün bir şekilde paketlemeyi kolaylaştırır.

- Eşleşmek için isteğe bağlı cihazlar vardır, örneğin Z tipi konveyör, çalışma platformu, tarih yazıcı, vesaire.

çok başlı tartım makinesinin teknik parametreleri

Çok başlı tartım makinemiz, çok başlı bir tartı ve yaka tipi paketleme makinesinden oluşmaktadır. Aşağıda, kombinasyon tartım makinesi ve yaka paketleme makinesinin belirli parametreleri hakkında bilgi bulacaksınız.

İsteğe bağlı kombinasyon ölçekleri

Yaygın çok başlı tartım makineleri 2 başlı, 4 başlı, 10 başlı, 14 başlı tartım makineleri vb. şeklindedir. Aşağıda kombinasyon tartım makinesi ile ilgili bazı parametre bilgileri yer almaktadır. Daha fazla bilgi almak isterseniz, bizimle iletişime geçmekten çekinmeyin!

| Çok başlı tartım cihazı | 2 kafalı kantar | 4 kafalı kantar | 10 kafalı kantar |

| Modeli | / | THDC-B4 | / |

| Paketleme spesifikasyonları | 500g-1000g (özelleştirilebilir) | 50-2000g | Maks. 3000g |

| Paketleme hızı | Dakikada 25-62 torba | 1200-2200 torba/saat | Maks. 60 torba/dakika |

| Kesinlik | ±0.5g | / | ±0.3-1.5 g |

| Voltaj gücü | 220v | AC220V 50Hz 500W | / |

| Makine boyutu | 750*1280*1950mm | 1200*600*1900mm | / |

| Ağırlık | 200kg | 260kg | / |

Lapel paketleme makinesinin Teknik verileri

Aşağıda çok başlıklı tartım makinesindeki yaka dikey paketleme makinesinin parametreleri bulunmaktadır. Mevcut üç tür vardır: SL-420, SL-520 ve SL-720. Her türün farklı bir torba uzunluğu ve genişliği vardır, lütfen detaylar için aşağıya bakın.

| Tip | SL-420 | SL-520 | SL-720 |

| Çanta uzunluğu | 80-300mm | 80-400mm | 100-400mm |

| Çanta genişliği | 50-200mm | 80-250mm | 180-350mm |

| Maksimum rulo film genişliği | 420mm | 520mm | 720mm |

| Paketleme hızı | 5-30 torba/dak | 5-50 torba/dak | 5-50 torba/dak |

| Ölçüm aralığı | 5-1000 ml | 3000ml(Maks.) | 6000ml(Maks.) |

| Hava tüketimi | 0,65mpa | 0,65mpa | 0,65mpa |

| Gaz tüketimi | 0,3m³/dak | 0,4m³/dak | 0,4m³/dak |

| Güç gerilimi | 220V | 220VAC/50HZ | 220VAC/50HZ |

| Boyut | (U)1320*(G)950*(Y)1360mm | (U)1150×(G)1795×(Y)1650mm | (U)1780×(G)1350×(Y)1950mm |

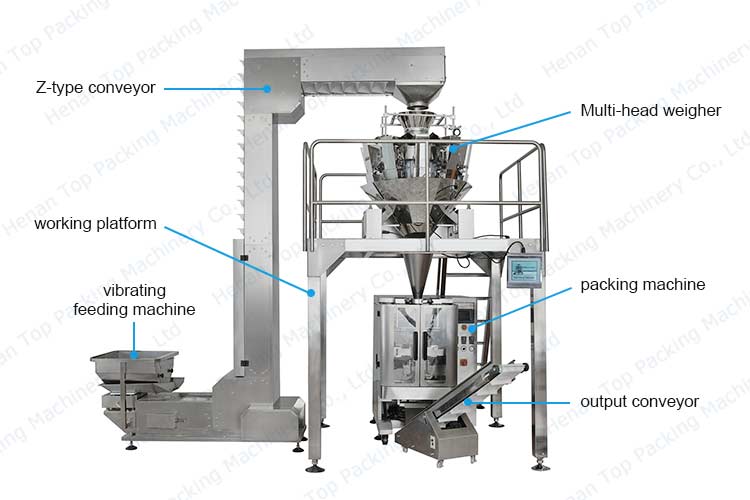

Çok başlıklı tartım makinesinin yapısı

Bu otomatik tartım ve doldurma makinesi, bir Z tipi konveyör, bir çalışma platformu, bir kombinasyon tartıcı, bir paketleme makinesi ve bir çıkış konveyörü içermektedir. Makine yapısı hakkında daha fazla bilgi edinmek için aşağıdaki resimlere bakın.

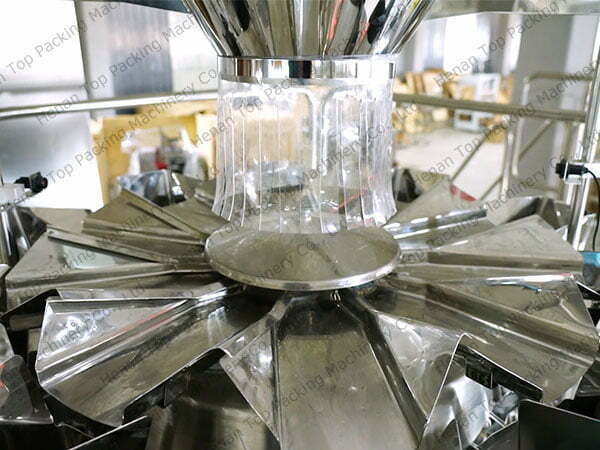

Çok başlı ağırlıklandırma

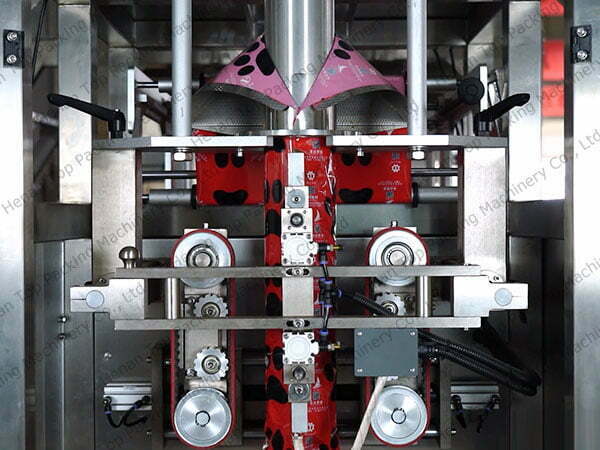

Lapel paketleme makinesinin ayrıntıları

Yaka dikey paketleme makinesi ile kombinasyon ölçeği nasıl çalışır?

Aslında, çok başlı tartım makinesinin iş akışı oldukça basittir, aşağıdaki gibidir:

- Besleme: Malzemeyi Z tipi elevatör ile çok başlı tartım bölümüne taşıyın.

- TartımDoğru tartım, her kafada bağımsız tartım sensörleri ile sağlanır. Hedef ağırlığa en yakın kombinasyon, makine ayarlarına göre "kombinasyon hesaplaması" ile otomatik olarak seçilir.

- Doldurma ve paketleme: Ardından, ilgili tartım haznesi otomatik olarak açılacak ve malzemeyi anında ve merkezi olarak altındaki torbaya boşaltacaktır.

- BoşaltmaMalzeme dikey ambalaj makinesine konulduktan sonra, otomatik olarak poşet yapma, doldurma, mühürleme, kesme vb. adımları tamamlayacak ve nihayetinde son ürün boşaltılacaktır.

Çok kafalı tartı paketleme makinesinin fiyatı nedir?

Çok başlı tartım ve paketleme makinesinin fiyatı, konfigürasyon, malzeme, paketleme hızı, paketleme ağırlık aralığı ve ek fonksiyonel modüllerin dahil edilmesi gibi birçok faktörden etkilenmektedir. Belirli malzeme, paketleme spesifikasyonları ve kapasite gereksinimlerine dayalı doğru bir teklif ve ekipman programı için bizimle iletişime geçmenizi öneririz.

Satılık multihead tartım makinesi için isteğe bağlı cihazlar

Ambalaj verimliliğini artırmak ve farklı ürün gereksinimlerine uyum sağlamak için çok başlı tartım ambalaj makinesi sistemi, genişletmek için çeşitli fonksiyonel modülleri destekler. Yaygın olarak tercih edilen ek ekipmanlar şunlardır:

Z tipi konveyör

Bu elevatör, elektronik bir tartım terazisi ile birlikte kullanılır ve otomatik besleme ve durdurma işlevini gerçekleştirmek için bir kontrol devresi ile malzeme seviyesi tarafından kontrol edilir. Müşterinin seçimi için paslanmaz çelik malzemeden ve karbon çeliğinden yapılmıştır.

- Taşıma kapasitesi: 3-6m³/saat

- Gerilim: 380V/220V

- Brüt ağırlık: 500kg

Çalışma platformu

Çalışma platformu, ekipmanı desteklemek ve sabitlemek için kullanılır, stabil bir çalışma ortamı sağlar ve paketleme makinesinin çalışması sırasında düzgünlük ve güvenliği garanti eder.

Çıktı konveyörü

Paketlenmiş bitmiş ürünleri bitmiş ürün alanına veya paketleme alanına taşımak için kullanılır.

Tarih yazıcısı

Poşetler üzerinde üretim tarihi, parti numarası, barkod ve diğer bilgilerin gerçek zamanlı olarak basılması.

Zincir torba cihazı

Bu, yüksek hacimli üretim için uygundur, üretim verimliliğini artırmak için otomatik sürekli poşetleme yapabilme kapasitesine sahiptir.

Nitrojen doldurma cihazı

Ürünün raf ömrünü uzatmak ve gıdanın tazeliğini korumak için torbadaki havayı nitrojen doldurarak değiştirir. Genellikle, raf ömrünü uzatması gereken şişirilmiş gıdalar, kuruyemişler ve diğer ürünler için kullanılır.

Delik delme cihazı

Hava geçirgenliği gerektiren ambalajlar için, taze sebzeler veya meyve ambalajı gibi, torbalara küçük delikler ekleyin.

Buna ek olarak, bizim çok başlı ağırlıklandırma paketleme makinemiz granül paketleme makinesi, hazır torba dolum makineleri, sızdırmazlık makinesi vb. ile çalışabilir.

Ürününüze uygun hangi konfigürasyonun olduğundan emin değilseniz, bize malzemenizi (ör. buz bloğu), torba türünü, gram ağırlığını ve kapasite gereksinimlerini gönderin, ve en uygun kombinasyon ölçekli paketleme çözümünü size önereceğiz.