دستگاه بسته بندی گرانول

| مدل پرفروش | SL-320 و SL-450 |

| برنامه های کاربردی | برنج، شکر، کلوچه، آجیل، دانه، غلات، ذرت بو داده، آب نبات، چیپس سیب زمینی و غیره. |

| گارانتی | 12 ماه |

| توجه داشته باشید | خدمات سفارشی در دسترس است |

معرفی مشتری

این دستگاه بسته بندی کیسه ای گرانول می تواند اقلام را در چوب یا ساشه با وزن های مختلف مانند 200 گرم، 600 گرم، 1000 گرم و غیره بسته بندی کند.

ما انواع مختلفی از دستگاه های بسته بندی گرانول را برای فروش داریم، مانند دستگاه بسته بندی گرانول کوچک (SL-320 & SL-450)، دستگاه بسته بندی سطلی زنجیره ای (SL-420) و توزین و بسته بندی چند سر.

علاوه بر این، ما از خدمات OME برای مطابقت با نیازهای بسته بندی شما پشتیبانی می کنیم. برای جزئیات بیشتر با ما تماس بگیرید!

فروش 3 نوع دستگاه بسته بندی کیسه ای گرانول اتوماتیک

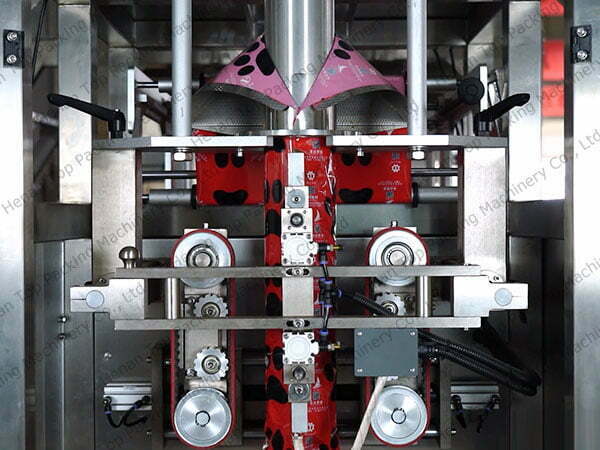

نوع 1: دستگاه بسته بندی گرانول عمودی کوچک

این نوع دستگاه بسته بندی گرانول پرکن اتوماتیک محبوب ترین پکیج گرانول است. 2 نوع موجود است: SL-320 و SL-450. برای جزئیات بیشتر به ادامه مطلب مراجعه کنید.

ارائه راه حل های دقیق به نیازها

این دستگاه می تواند گرانول را در کیسه هایی با وزن ≤200 گرم بسته بندی کند. می تواند 20-80 کیسه در دقیقه بسته بندی کند. سبک کیف می تواند مهر و موم پشت و مهر و موم 3 طرفه باشد. مهر و موم 4 طرفه نیز می تواند سفارشی شود.

این دستگاه از فولاد ضد زنگ ساخته شده است و حداکثر عرض فیلم آن ≤۳۰ سانتی متر است.

بر اساس نیازهای بسته بندی واضح مشتری، ما به سرعت پاسخ دادیم و راه حل های زیر را ارائه دادیم:

این نوع دستگاه بسته بندی گرانول دارای وزن بسته بندی ≤600 گرم می باشد. همچنین می تواند 20-80 کیسه در دقیقه بسته بندی کند. سبک بسته بندی آن مهر و موم پشت و مهر و موم 3 طرفه است. با توجه به نیاز شما، ما همچنین می توانیم مهر و موم 4 طرفه را سفارشی کنیم.

مواد دستگاه فولاد ضد زنگ و mx است. عرض فیلم ≤43 سانتی متر است.

عرض کیسه 20-200 میلی متر و طول آن 30-180 میلی متر است (قابل تنظیم).

| مدل | SL-320 | SL-450 |

| ظرفیت | 20-80 کیسه در دقیقه | 20-80 کیسه در دقیقه |

| وزن بسته بندی | ≤200 گرم | ≤600 گرم |

| قدرت | 1.8 کیلووات | 2.2 کیلووات |

| سبک کیف | مهر و موم پشت یا مهر و موم 3 طرفه | مهر و موم پشت یا مهر و موم 3 طرفه |

| اندازه | 650*1050*1950 میلی متر | 750*750*2100 میلی متر |

| وزن | 250 کیلوگرم | 420 کیلوگرم |

ارسال ویدئوی تولید دستگاه

دستگاه بسته بندی گرانول کیسه ای چرخشی اتوماتیک Shuliy از قیف، فنجان های حجمی، کنترل پنل، کیسه ساز، دستگاه آب بندی و برش و ... ساخته شده است، علاوه بر این، این دستگاه می تواند چاپگر خرما را نیز تجهیز کند.

جزئیات ساختار برای مرجع شما برای درک بهتر اجزای دستگاه در زیر نشان داده شده است.

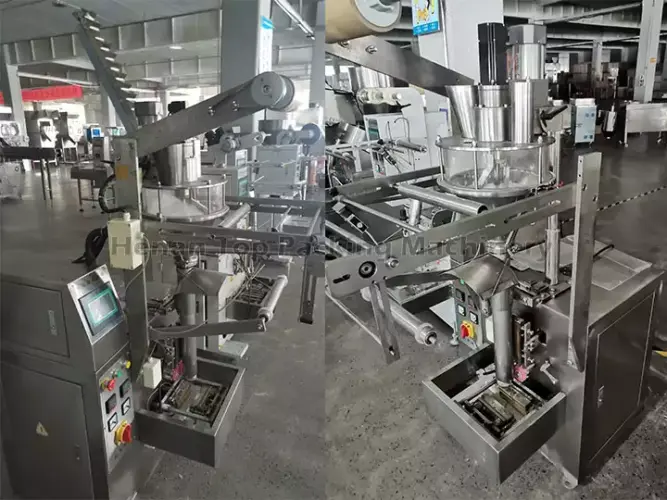

نوع 2: دستگاه بسته بندی سطل زنجیره ای

برای اندازه بسته بندی مشتری، ویژگی های محصول و الزامات ولتاژ، ما دو برنامه قیمت گذاری برای انتخاب مشتریان ارائه می دهیم.

این دستگاه بسته بندی کیسه ای گرانول می تواند 30-60 کیسه در دقیقه بسته بندی کند. وزن بسته بندی آن بین 100-1000 میلی لیتر است.

سبک بسته بندی می تواند مهر و موم 4 طرفه، مهر و موم 3 طرفه و مهر و موم پشت باشد.

می تواند به طور خودکار مجموعه ای از اقدامات از جمله ساخت کیسه، پر کردن، شمارش، مهر و موم کردن و برش محصولات نهایی را انجام دهد.

| مدل | SL-420 |

| ظرفیت | 30-60 کیسه در دقیقه |

| حداکثر عرض فیلم | 430 میلی متر |

| طول کیسه | 30-280 میلی متر |

| ولتاژ | 220/380 ولت |

| توان کل | 1.2 کیلووات |

| حداکثر قطر بیرونی کاغذ رول | ≤Φ350 میلی متر |

| ضخامت فیلم بسته بندی | 0.03-0.10 میلی متر |

| محدوده اندازه گیری | 100-1000 میلی لیتر |

| وزن دستگاه | 400 کیلوگرم |

| اندازه ماشین | 870*1350*1850mm |

پاسخ به سوالات مشتریان به طور دقیق در مورد مواد دستگاه بسته بندی، اثر دوخت، کارایی بسته بندی و غیره، برای افزایش اعتماد مشتری.

ساختار این دستگاه آسان است. این دستگاه از صفحه نمایش لمسی، قیف، محور فیلم، سازنده کیسه، چرخ ها و غیره تشکیل شده است. اگر جزئیات بیشتری می خواهید، همین حالا با ما تماس بگیرید!

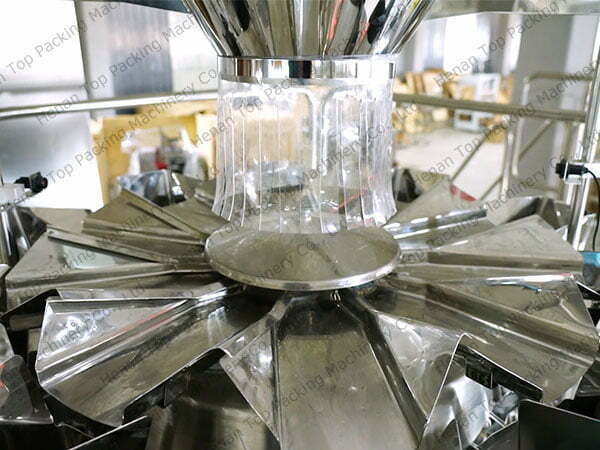

نوع 3: دستگاه بسته بندی توزین چند سر

دستگاه توزین و بسته بندی چند سر

این دستگاه از توزین چند سر، واحد بسته بندی اتوماتیک، آسانسور Z و سکوی کار تشکیل شده است.

دارای خروجی 5-50 کیسه در دقیقه و وزن بسته بندی 150-6000 میلی لیتر است.

مدل کیف می تواند کیف بالشی، کیف ایستاده، پانچ و غیره باشد. می تواند یک کیف یا چند کیسه باشد.

انواع مختلفی از توزین های چند سر وجود دارد که می توانید از بین آنها انتخاب کنید. برخی برای مرجع شما ذکر شده است.

| توزین چند سر | توزین 2 سر توزین 4 سر توزین 10 سر توزین 14 سر |

پارامترهای دستگاه بسته بندی اتوماتیک مورد استفاده برای دستگاه بسته بندی توزین چند سر

| مدل | SL-420 | SL-520 | SL-720 |

| طول کیسه | 80-300 میلی متر | 80-400 میلی متر | 100-400 میلی متر |

| عرض کیسه | 50-200 میلی متر | 80-250 میلی متر | 180-350 میلی متر |

| عرض فیلم | 420 میلی متر | 520 میلی متر | 720 میلی متر |

| سرعت بسته بندی | 5-30 کیسه در دقیقه | 5-50 کیسه در دقیقه | 5-50 کیسه در دقیقه |

| محدوده اندازه گیری | 150-1200 میلی لیتر | حداکثر 3000 میلی لیتر | حداکثر 6000 میلی لیتر |

| ولتاژ | 220 ولت | 220VAC/50HZ | 220VAC/50HZ |

| قدرت | 2.2 کیلووات | 4 کیلو وات | 5 کیلو وات |

| بعد | 1320*950mm*1360mm | 1150*1795*1650 میلی متر | 1780*1350*1950 میلی متر |

| وزن دستگاه | 540 کیلوگرم | 600 کیلوگرم | / |

اگر می خواهید از این دستگاه بسته بندی گرانول تمام اتوماتیک استفاده کنید، یک دستگاه توزین چند سر و دستگاه بسته بندی اتوماتیک همسان را انتخاب کنید. برای جزئیات بیشتر با ما در تماس باشید!

دستگاه تونل حرارتی

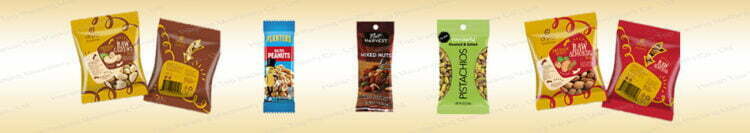

محصولات گرانول مناسب برای دستگاه بسته بندی گرانول اتوماتیک

دستگاه بسته بندی گرانول ما دارای طیف گسترده ای از کاربردها است، مانند:

پس از اینکه مشتری قصد خرید را تأیید کرد، ما وارد مرحله تأیید جزئیات شدیم. با این حال، در قیمتگذاری نهایی، مشتری متوجه شد که قدرت تجهیزات و روش سیمکشی قدرت نیاز به تنظیمات اضافی دارد. برای حل سریع مشکل، ما اقدامات زیر را انجام دادیم:

دستگاه های بسته بندی گرانول با طراحی منطقی و ساختار پیشرفته می توانند اندازه گیری، پر کردن، ساخت کیسه، چاپ تاریخ انقضا و خروجی محصول را به طور خودکار در یک مرحله به پایان برسانند. این کار راحت و مقرون به صرفه است.

سبک کیف متنوع است، مانند پانچ، چوب، ساشه، گوشه های چنگال، مهر و موم پشت، مهر و موم 3 طرفه، مهر و موم 4 طرفه و غیره.

ما مواد بسته بندی مختلفی در دسترس داریم، به عنوان مثال،

پلی استر / آلومینیوم / پلی اتیلن، پلی پروپیلن / پلی اتیلن فویل آلومینیوم / پلی اتیلن، نایلون / پلی اتیلن پیشرفته، کاغذ فیلتر برگ چای، کاغذ / پلی اتیلن و غیره.

ویژگی های تجهیزات بسته بندی گرانول

- می تواند به طور خودکار تکمیل شود کیسه سازی، اندازه گیری، تغذیه، پر کردن، مهر و موم کردن، برش، شمارش و چاپ، و می تواند عملکرد پارگی آسان را افزایش دهد.

- دستگاه بسته بندی کیسه ای گرانول می باشد ساخته شده از فولاد ضد زنگ 304، دوام و عمر طولانی.

- با یک سیستم کنترل پیشرفته PLC و الف صفحه نمایش رنگی لمسی 5 اینچی، یک کارگر برای راه اندازی آن کافی است.

- سبک کیف می تواند باشد مهر و موم پشت، مهر و موم 3 طرفه و مهر و موم 4 طرفه.

- دستگاه بسته بندی گرانول شولی دارای کاربردهای گستردهمانند برنج، شکر، لوبیا، چای، چیپس و غیره.

- ما می توانیم سفارشیسازی قدرت، ولتاژ، ظاهر دستگاهو غیره متناسب با کسب و کار شما.

دستگاه بسته بندی گرانول Shuliy چگونه کار می کند؟

فرآیند کار دستگاه بسته بندی دانه ای عمدتاً به مراحل زیر تقسیم می شود:

- قرار دادن مواد

- ابتدا مواد گرانولی را که قرار است بسته بندی شود در قیف قرار دهید.

- اندازه گیری

- دستگاه بسته بندی گرانول ما با استفاده از دستگاه دوز، مواد را با دقت وزن می کند.

- کیسه سازی

- پس از توزین، دستگاه به طور خودکار کیسه ها را آماده می کند. معمولاً دستگاه طول مشخصی از مواد فیلم را از رول برش می دهد تا کیسه ای تشکیل شود.

- پر کردن

- مواد دوز شده از طریق درگاه پر کردن به کیسه آماده شده عبور می کند. این فرآیند باعث می شود که مواد به طور دقیق در کیسه پر شوند.

- آب بندی

- هنگامی که پر کردن کامل شد، دستگاه به طور خودکار کیسه را مهر و موم می کند. به طور کلی، از فناوری آب بندی حرارتی برای آب بندی قسمت باز کیسه استفاده می شود تا از ایمنی و تازگی مواد اطمینان حاصل شود.

- برش و تخلیه

- در نهایت، دستگاه فیلم را در ناحیه آب بندی برش می دهد و محصول بسته بندی شده را به طور خودکار تخلیه می کند.

قیمت دستگاه بسته بندی گرانول چقدر است؟

قیمت دستگاه بسته بندی گرانول Shuliy با عوامل زیادی مانند مواد، هزینه حمل و نقل، هزینه مالیات، پارامترها و غیره ارتباط نزدیکی دارد. هر عاملی می تواند تا حد زیادی بر هزینه تجهیزات بسته بندی گرانول تأثیر بگذارد.

به عنوان مثال، هزینه حمل و نقل به شدت افزایش می یابد و هزینه دستگاه بسته بندی افزایش می یابد. و هزینه دستگاه بسته بندی بزرگ گران تر از هزینه دستگاه بسته بندی کوچک است.

اگر می خواهید قیمت دستگاه بسته بندی کیسه گرانول را بدانید، لطفا با ما تماس بگیرید و ما می توانیم بهترین قیمت را به شما ارائه دهیم.

چگونه از دستگاه بسته بندی گرانول نگهداری کنیم؟

- بازرسی منظم قطعات

- به طور منظم قطعات دستگاه را بررسی کنید تا مطمئن شوید که آنها به طور انعطاف پذیر می چرخند. برای جلوگیری از تأثیرگذاری بر عملکرد عادی دستگاه، عیوب را تعمیر کنید.

- نظافت بعد از خرابی

- هنگامی که دستگاه برای مدت طولانی متوقف می شود، کل دستگاه باید پاک شود تا تمیز بماند.

- به قطعات الکتریکی دقت کنید

- قطعات الکتریکی باید به ضد آب، رطوبت و ضد خوردگی توجه کنند. مطمئن شوید که جعبه کنترل الکتریکی و پایانه ها تمیز نگه داشته می شوند تا از خرابی الکتریکی جلوگیری شود.

- عیب یابی رایج

- مشکلات متداول دستگاه بسته بندی گرانول کیسه ای چرخشی اتوماتیک شامل خرابی پنل کنترل، سیستم توزین یا مکانیزم پر کردن است. شما باید به موقع این مشکلات را برطرف کنید.

چرا از دستگاه بسته بندی گرانول اتوماتیک استفاده کنیم؟

استفاده از دستگاه بسته بندی گرانولی Shuliy مزایای بی شماری دارد، از جمله:

- افزایش سرعت و دقت بسته بندی

- این دستگاه می تواند سرعت و دقت فرآیند بسته بندی را به میزان قابل توجهی افزایش دهد و در نتیجه کارایی و بهره وری را بهبود بخشد.

- بهبود قوام و یکنواختی محصولات بسته بندی شده.

- دستگاه ما می تواند قوام و یکنواختی محصولات بسته بندی شده را بهبود بخشد.

- کاهش هزینه های نیروی کار و مواد.

- می تواند هزینه های نیروی کار و مواد را کاهش دهد.

تولید کنندگان دستگاه بسته بندی کیسه ای گرانول از چین

به عنوان یکی از تولید کنندگان پیشرو دستگاه بسته بندی گرانول در چین، محصولات ما هم از نظر کیفیت و هم از نظر قیمت بسیار رقابتی هستند.

- اولا، ما تجربه غنی در طراحی، تحقیق، ساخت و بازاریابی ماشین آلات بسته بندی داریم. ما یک سیستم زنجیره تامین بالغ و سیستم کنترل کیفیت ایجاد کرده ایم.

- ثانیا، ویژگی های مستقیم کارخانه باعث رقابتی تر شدن محصول ما می شود. قیمت تجهیزات بسته بندی گرانول ما نسبت به بسیاری دیگر از تولید کنندگان دستگاه های بسته بندی مطلوب تر است.

- ثالثاً، Shuliy دارای قابلیت قوی برای ارائه خدمات OEM برای مطابقت دقیق با نیازهای خاص شما است.

برای بهترین قیمت با ما تماس بگیرید!

آیا به دنبال تجهیزات بسته بندی گرانول هستید؟ برای اطلاعات بیشتر و بهترین قیمت ها همین امروز با ما تماس بگیرید.