新加坡客户成功订购辣椒酱膏体包装机

为满足客户需求,实现高效辣椒酱包装,新加坡客户通过我们的专业服务成功采购了一台酱料包装机。以下是该案例的详细回顾。

客户背景及需求

来自新加坡的客户是一家以生产辣椒酱为主的食品企业。其核心需求是提高生产效率,同时保证包装的精美程度和一致性。

通过与客户的详细沟通,客户对酱料包装机的具体订单需求如下:

- 功能要求:具有搅拌功能,保证酱汁的均匀性

- 包装要求:三边封、易撕设计

- 包装规格:每包21-24克

- 膜宽:18cm

- 电压:220V,50Hz

- 清关:双清到门

我们的解决方案

客户面临的主要问题是传统包装效率低下,人工操作容易导致包装不一致,辣椒酱容易沉淀影响包装质量。

根据客户的要求,我们推荐了带有搅拌功能的酱料袋包装机,它可以保持酱料的均匀性,避免在包装过程中出现分层现象。此外,带易撕功能的三边封设计提升了包装体验,满足了市场需求。

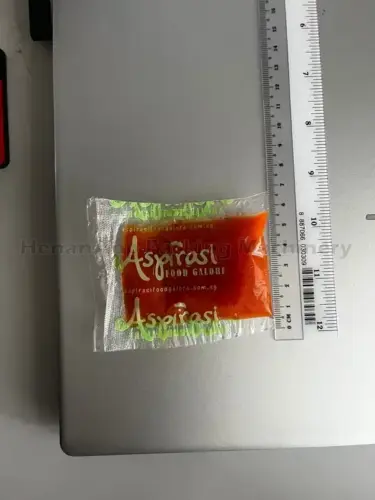

为新加坡客户测试膏体包装机性能:辣椒酱包装机

新加坡采购订单详细信息

- 模型: 320

- 包袋款式:三边封

- 包装速度:24-60袋/分钟

- 袋长:30-180毫米

- 袋宽:25-145mm(需更换前者)

- 灌装范围:2-100毫升

- 重量:280公斤

- 空气压力:0.6-0.7MP

- 方面:1150*700*1750mm

- 具有易撕直边

- 具有搅拌功能(辣椒和糖)

设备抵达客户工厂后,顺利完成了安装调试。客户对包装效果和设备性能非常满意,特别是搅拌功能和包装精度得到了高度评价。

客户表示期待未来继续合作,进一步提升辣酱(辣椒膏)包装的自动化水平,参见相关条目 辣椒酱 的包装。